■ Built in DSP digital signal processor

■ Built in envelope value frequency domain

■ Built in speed frequency domain

■ Built in acceleration vibration sensor

■ Equipped with RS485 digital bus interface

■ Built in FFT spectrum analysis

■ Built in acceleration time-domain and frequency-domain waveform output

■ Customizable three-axis output

YD285 digital vibration sensor is a low-cost vibration sensor with built-in digital processor (DSP) and RS485 standard industrial bus. It can directly convert mechanical vibration signals into digital waveform data and convert it into frequency spectrum, which is transmitted to PLC/DCS/computer through the sensor's RS485 interface. Stainless steel waterproof shell material, suitable for humid environments.

YD285 is an accelerometer that is highly suitable for power plants, paper mills, gas turbines, and other extensive industrial applications. The knowledge and experience gained in these demanding fields are also applied in some small-scale applications, such as diesel engines, water pumps, generators, etc. Introduce an integrated analysis vibration sensor with built-in analog-to-digital conversion high-frequency sampling, with a sampling rate of 25.6kHz. The collected acceleration data is windowed (Hanning window) and FFT (Fourier transform) analyzed by a DSP signal processor, resulting in a frequency spectrum of 3200 spectral lines with an analysis bandwidth of 10kHz. The sensor outputs the spectrum through the RS485 bus, and the output mode can be single transmission or continuous update transmission, with an update rate of 0.32 seconds for a 3200 line spectrum. The transmission mode is changed by PLC/DCS/computer transmitting instructions through RS485 bus.

Up to 64 vibration sensors can be connected to form a vibration measurement network, and a host (such as a PC computer) connected to this network can read vibration data, analyze, process, and display the data.

The significance of envelope value is very important:

1: Acceleration envelope is a monitoring method that extracts high-frequency signals from equipment vibration signals and processes them separately. It is particularly sensitive to impact signals. The frequency distribution on the envelope spectrum can be used to determine the surface damage of gears and bearings, and the severity of the fault can be determined based on the magnitude of the amplitude. Envelope monitoring is a sensitive parameter for detecting early defects in bearings. Bearing failure begins at the fatigue stress concentration point below the raceway surface. At this time, acoustic emission sensors can be used to detect the elastic wave signal of bearing fatigue damage. When the damage develops to the raceway surface and produces fine cracks, the resulting impact signal can be detected using acceleration envelope technology. Traditional vibration velocity signals can only be detected when the surface defects of the raceway develop to a very serious level. Therefore, acceleration envelope monitoring is the most widely used and effective early bearing defect signal processing technology in the field of bearing status.

2: For rolling bearing equipment, using envelope values to analyze operating conditions can more intuitively determine equipment faults, rather than vibration speed. Because many devices have vibration speeds within the normal range, but the envelope value may already be very high, indicating that the bearing has failed and needs to be dealt with immediately. If not handled, it may cause greater losses.

3: In other cases, the vibration speed may indeed exceed the standard alarm value or even the trip value, but if other reasons can be ruled out and the envelope value is within a reasonable range, the equipment still does not need to be stopped for maintenance.

Electric motors generally use rolling bearings, and faults occur as bearing defect frequencies in the envelope spectrum and edge frequency components containing shaft rotation frequency.

1.Vibration sensorPiezoelectric type

2. Sensor typeacceleration

3. Vibration measurement range±50g

4 .Vibration resolution16 bits

5. Frequency range0.5-1kHz acceleration

6. Sample Rate25.6kHz

7.Dynamic range>90dB

8. Nonlinear0.2% (full range)

9. Data interfaceRS485 standard industrial bus

10. The maximum number of networked sensors is 64

11. power supply15-24Vdc

12. Operating environment-40℃~+85℃

13. weightAbout 450g

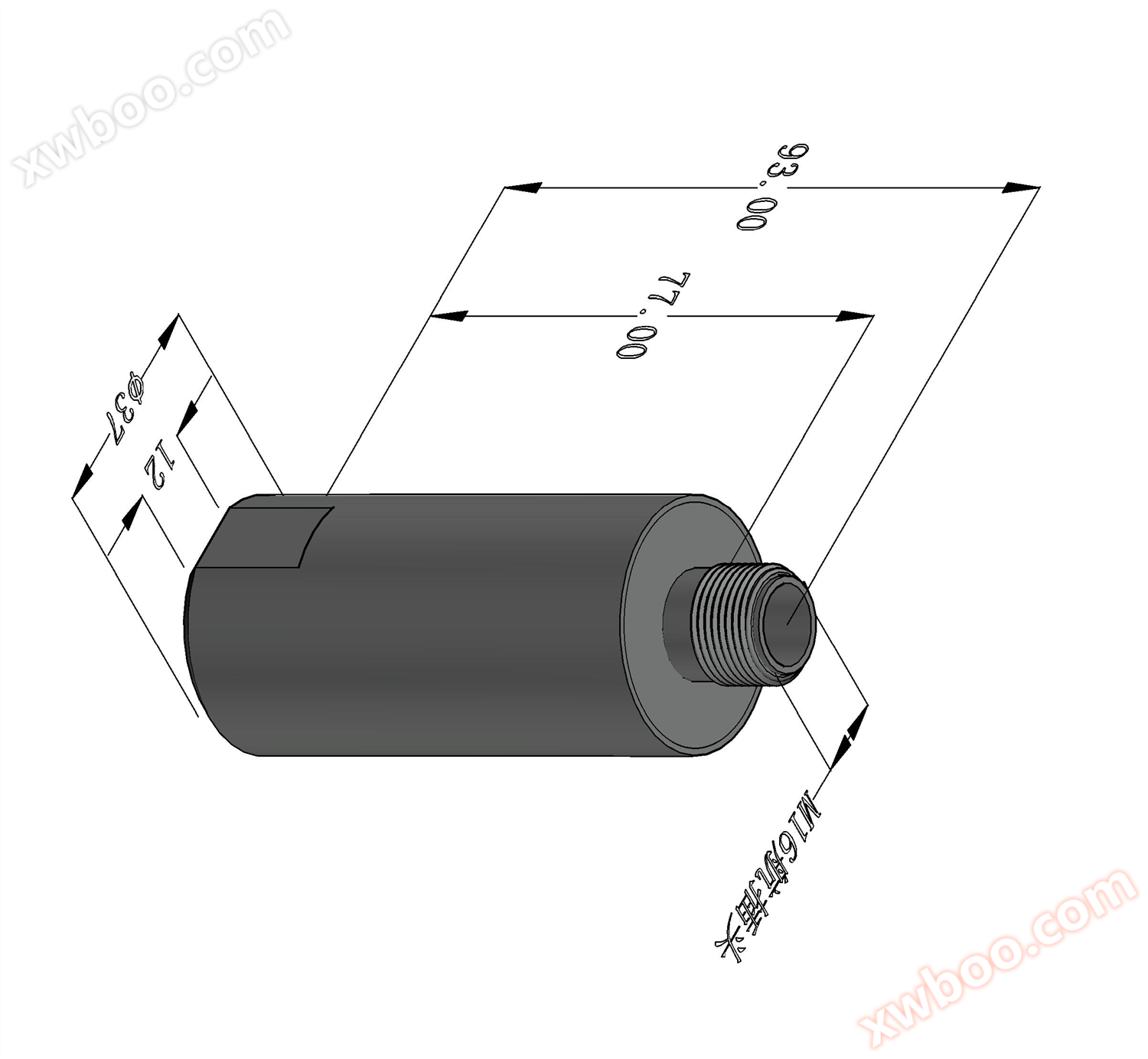

14. sizePlease refer to the following figure for detailed information

15. material304 stainless steel

External dimensions

Definition of vibration sensor lead:The YD285 vibration sensor adopts an anti vibration stainless steel hose lead structure, and a 4-core (6-core) shielded cable provides power and RS485 for the sensorThe definition of communication and signal is distinguished by different cable colors. The following figure illustrates the definition of sensor signal.

Cable Signal Definition Table(For reference only, subject to factory definition)

If spectrum analysis can predict equipment failures, then envelope monitoring can serve as a sign of failure. Predicting early equipment failures plays a very important role.

The schematic diagram of envelope value processing is as follows:

Spectrum diagram

10KHz 1.15V peak frequency spectrum

9.5KHz 1.26V Peak spectrum diagram

6KHz 1.5V peak frequency spectrum

3.125Hz 0.75V peak spectrum diagram

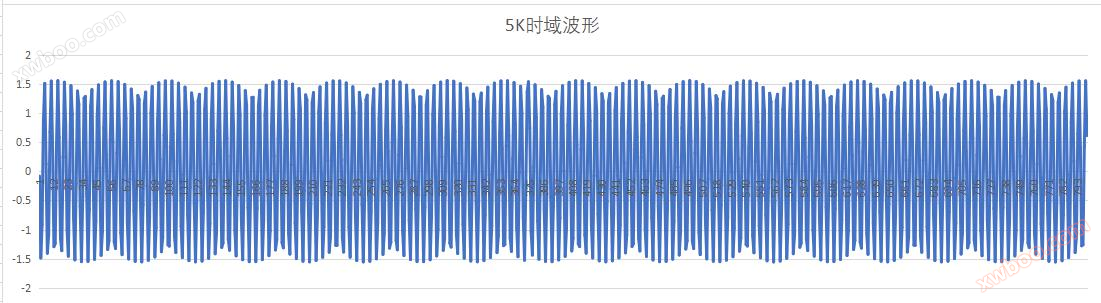

Time domain waveform diagram

1KHz 1.5V Peak spectrum diagram

5KHz 1.5V peak frequency spectrum

9500Hz 1.2V peak frequency spectrum

1KHz 1G

5KHz 1G

9.5KHz 1G

1KHz 1G