WQ type sewage pump

1、 Applicable places

The discharge of sewage from hospitals and hotels, the discharge of severely polluted wastewater from market engineering construction sites, factories and commercial areas, sewage discharge stations in residential areas, urban sewage treatment plant drainage systems, domestic sewage, urban sewage treatment plant drainage systems, civil air defense system drainage stations, water supply from water plants, and irrigation of farmland.

2、 Product Overview:

1. Adopting a large channel anti clogging hydraulic component design greatly improves the ability of pollutants to pass through, effectively passing through 5 times the fiber material of the pump diameter and solid particles with a diameter of about 50% of the pump diameter.

2. Reasonable design, reasonable matching motor, high efficiency, significant energy-saving effect.

3. The mechanical seal adopts a dual channel series seal, made of hard and wear-resistant tungsten carbide, which has the characteristics of durability and wear resistance, and can ensure the safe and continuous operation of the pump for more than 800 hours.

4. The pump structure is compact, small in size, easy to move, and easy to install, without the need to build a pump room. It can work underwater, greatly reducing project costs.

5. There is an oil-water probe installed in the pump oil chamber. When the mechanical seal on the pump side is damaged and water enters the oil chamber, the probe generates a signal to protect the pump.

6. A fully automatic safety protection control cabinet can be equipped according to user needs to monitor pump leakage, electric leakage, overload, and overheating, ensuring reliable and safe pump operation.

3、 Installation, operation, and maintenance prompts

It is strictly prohibited to forcefully pull the cable when installing and transporting the electric pump, in order to avoid causing internal cable breakage, joint bonding, etc., which may cause the pump to malfunction or even burn out the motor.

Please use the electric pump cable grounding wire for correct and reliable grounding during installation. When the electric pump is working, it is strictly prohibited for people or animals to approach the working water area or touch the electric pump. In order to reduce electrical risks, it can only be connected to an appropriate grounding socket.

Overloading operation is strictly prohibited

The cable used with the pump must not be less than 1.2 times the cable area of the electric pump.

During installation, the electric pump must be securely fastened, but the cable must not be subjected to force or rotate together with the start and stop of the electric pump.

When the pump fails to discharge water during operation, it should be checked whether the electric pump is reversing or if the air inside the check valve at the outlet of the electric pump has not been completely discharged.

Regularly check the insulation resistance between phases and relative ground of the electric pump motor, which should not be less than 2MQ. Otherwise, it should be disassembled for maintenance.

After six months of normal operation under specified working conditions, the sealing condition of the oil chamber of the electric pump should be checked. If the oil in the oil chamber is emulsified or water precipitates out, the 10 # engine oil and mechanical seals should be replaced in a timely manner.

After one year of normal operation of the electric pump, a major overhaul should be carried out to replace worn and vulnerable parts, check the condition of fasteners, and replenish and replace lubricating grease to ensure good lubrication of the electric pump during operation.

If the electric pump is not in use, please clean it thoroughly and wipe off any water droplets to prevent rusting

If you have any questions, you can call: 021-57239999 orClick to consult experts for selection and quotation

4、 Common fault analysis and troubleshooting methods:

|

Fault phenomenon

|

cause analysis

|

Troubleshooting

|

|

Insufficient flow or no water output

|

1Wrong rotation direction of impeller

2Is the outlet valve open and intact

3The impeller of the pipeline is blocked

4The speed is too low

5The head is too high

6High density of pumping medium

7High viscosity of the medium

8Wear at the sealing ring mouth

|

1Adjust the rotation direction of the impeller

2Check, repair, and eliminate

3Clean up debris

4Check electrical equipment and circuits

5Change the pump or reduce the head

6Dilute with water to reduce concentration

7Reduce viscosity

8Replace

|

|

Unstable operation

|

1Unbalanced impeller

2Bearing damage

|

1Send to the manufacturing plant for replacement or calibration

2Replace

|

|

The pump cannot start

|

1Lack of phase

2The impeller is stuck

3Winding, connector or cable open circuit

4The stator winding is burnt out

5Electrical control malfunction

|

1Check the circuit for repair

2Remove debris

3Check and repair with an ohmmeter

4Repair and replace the winding

5Repair or replace

|

|

Excessive current

|

1Low working voltage

2Pipeline and impeller are blocked

3The height or viscosity of the liquid being pumped is relatively high

4Using a low head

|

1Adjust the working voltage

2Clean up pipeline and impeller blockages

3Change density and viscosity

4Reduce flow and increase head

|

|

Low insulation resistance

|

1Leakage at the power supply terminal of the cable

2Cable damage

3Mechanical seal wear leads to leakage

4EachOFailure of the sealing ring

5The casing is corroded by the medium and leaks water

|

1Tighten the compression nut

2Replace

3Replace

4Replace

5Repair

|

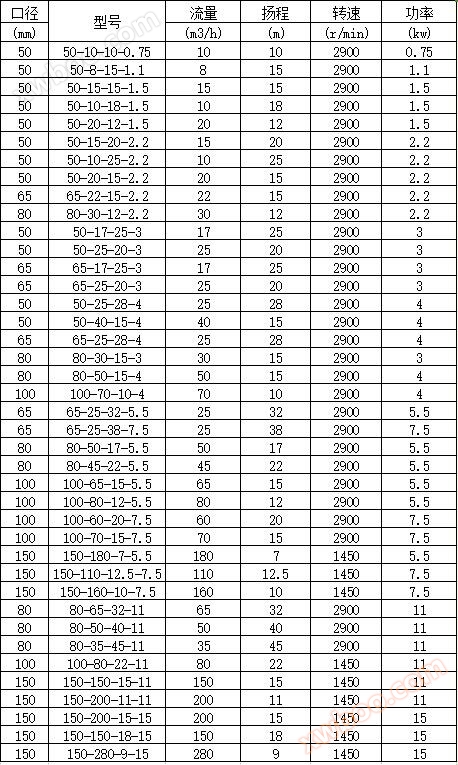

5、 Performance parameter table: