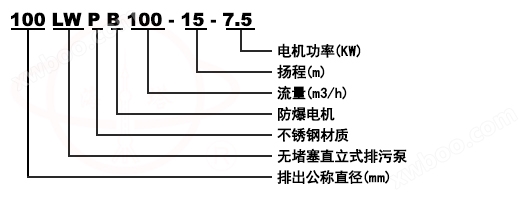

Model meaning

Product Introduction

The WL/LW non clogging upright sewage pump is a new generation of pump products developed based on the characteristics of water pump use, with features such as anti winding, non clogging, automatic installation, and automatic control. It is effective in transporting solid particles and long fiber waste.

The WL/LW unobstructed vertical sewage pump adopts a unique impeller structure and a new mechanical seal, which can effectively transport solid substances and long fibers.

Compared with traditional impellers, the impeller of this pump adopts a single channel or double channel form, which is similar to a curved pipe with the same cross-sectional size and has very good flow characteristics. Coupled with a reasonable volute chamber, the pump has high efficiency and the impeller has undergone dynamic and static balance tests, making the pump operate without vibration.

The hydraulic performance of the WL/LW unobstructed vertical sewage pump is advanced and mature. After testing, all performance indicators of the product have reached the relevant standards and regulations. After its launch on the market, the product has been welcomed and praised by users for its effectiveness, reliable performance, and stable quality.

Product Features

1. Adopting a double blade impeller structure greatly improves the ability of pollutants to pass through

2. The mechanical seal adopts a new type of friction pair and operates in the oil chamber for a long time;

3. The overall structure is compact, small in size, low in noise, easy to maintain, and convenient for users to replace;

4. The automatic control cabinet can automatically control the pump's over movement and stop according to the required liquefaction changes, without the need for dedicated personnel to supervise, making it extremely convenient to use;

5. Installation methods can be provided according to user needs, which greatly facilitates installation and maintenance. People do not need to enter the sewage pit for this purpose;

6. Can be used within the design scope while ensuring that the motor does not overload;

7. If the pump is equipped with an outdoor motor, there is no need to build a pump room, and it can be directly installed and used outdoors to save costs;

Product Usage

WL/LW unobstructed vertical sewage pump is suitable for the discharge of severely polluted wastewater in factories and commercial areas, sewage discharge stations in main residential areas, water distribution systems in urban sewage treatment plants, drainage stations in civil air defense systems, water supply equipment in waterworks, sewage discharge in hospitals and hotels, municipal engineering construction sites, mining supporting machinery, rural biogas digesters, farmland irrigation and other industries. It can also be used for conveying granular sewage and pollutants, as well as for clean water and weakly corrosive media.

working conditions

1. The sewage pump series products are suitable for rated voltage of 380V and power frequency of 50Hz

2. The temperature of the medium does not exceed 40 degrees Celsius, and the density of the medium is ≤ 1150kg/m3, The pH value is between 5-9;

3. Altitude not exceeding 1000 meters;

4. The annual viscosity of the conveying medium shall not exceed 1000CP;

5. The main material of the product is cast iron and cannot be used in highly corrosive or corrosive media;

Attention: Before selecting or installing, make sure that the actual usage conditions of the pump comply with the above terms to ensure the correct use of the product!

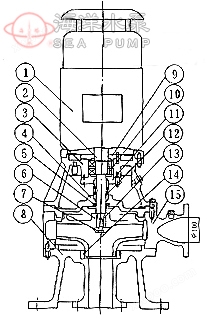

Structure diagram

|

Serial number |

name |

Serial Number |

name |

1 |

electric machinery |

9 |

bearing gland |

|

2 |

Extended shaft |

10 |

Bearing |

|

3 |

Bearing seat |

11 |

Mechanical seal seat |

|

4 |

Pump cover |

12 |

mechanical seal |

|

5 |

oil seal |

13 |

key |

|

6 |

impeller |

14 |

Wear resistant ring of pump body |

|

7 |

IMPELLER NUT |

15 |

pump body |

|

8 |

base |

performance parameter

model |

caliber |

internet traffic |

lift |

rotational speed |

power |

efficiency |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|

25-7-8-0.55 |

25 |

7 |

8 |

2900 |

0.55 |

45 |

25-8-22-1.1 |

25 |

8 |

22 |

2900 |

1.1 |

45 |

32-8-12-0.75 |

32 |

8 |

12 |

2900 |

0.75 |

48 |

32-12-15-1.1 |

32 |

12 |

15 |

2900 |

1.1 |

45 |

40-15-15-1.5 |

40 |

15 |

15 |

2900 |

1.5 |

48 |

40-15-30-2.2 |

40 |

15 |

30 |

2900 |

2.2 |

54 |

50-20-7-0.75 |

50 |

20 |

7 |

2900 |

0.75 |

51 |

50-10-10-0.75 |

50 |

10 |

10 |

2900 |

0.75 |

52 |

50-20-15-1.5 |

50 |

20 |

15 |

290 |

1.5 |

53 |

50-15-25-2.2 |

50 |

15 |

25 |

2900 |

2.2 |

54 |

50-18-30-3 |

50 |

18 |

30 |

2900 |

3 |

55 |

50-40-15-4 |

50 |

40 |

15 |

2900 |

4 |

55 |

50-25-32-5.5 |

50 |

25 |

32 |

2900 |

5.5 |

55 |

50-20-40-7.5 |

50 |

50 |

20 |

2900 |

7.5 |

58 |

65-25-15-2.2 |

65 |

25 |

15 |

2900 |

2.2 |

50 |

65-37-13-3 |

65 |

37 |

13 |

2900 |

3 |

57 |

65-25-30-4 |

65 |

25 |

30 |

2900 |

4 |

61 |

65-30-40-7.5 |

65 |

30 |

40 |

2900 |

7.5 |

56 |

65-35-50-11 |

65 |

35 |

50 |

2900 |

11 |

45 |

65-35-60-15 |

65 |

35 |

60 |

2900 |

15 |

65 |

80-40-7-2.2 |

80 |

40 |

7 |

1450 |

2.2 |

59 |

80-43-13-3 |

80 |

43 |

13 |

2900 |

3 |

70 |

80-40-15-4 |

80 |

40 |

15 |

2900 |

4 |

61 |

80-60-13-5.5 |

80 |

60 |

13 |

2900 |

5.5 |

67 |

80-65-25-7.5 |

80 |

65 |

25 |

2900 |

7.5 |

63 |

model |

caliber |

internet traffic |

lift |

rotational speed |

power |

efficiency |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|

100-80-10-4 |

100 |

100 |

10 |

1450 |

4 |

65 |

100-100-15-7.5 |

100 |

100 |

15 |

1450 |

7.5 |

68 |

100-80-20-7.5 |

100 |

80 |

20 |

1450 |

7.5 |

65 |

100-100-25-11 |

100 |

100 |

25 |

1450 |

11 |

70 |

100-100-30-15 |

100 |

100 |

30 |

1450 |

15 |

65 |

100-100-35-18.5 |

100 |

100 |

35 |

1450 |

18.5 |

68 |

125-130-15-11 |

125 |

130 |

15 |

1450 |

11 |

72 |

125-130-20-15 |

125 |

130 |

20 |

1450 |

15 |

75 |

150-145-9-7.5 |

150 |

145 |

9 |

1450 |

7.5 |

76 |

150-180-15-15 |

150 |

180 |

15 |

1450 |

15 |

69 |

150-180-20-18.5 |

150 |

180 |

20 |

1450 |

18.5 |

72 |

150-180-25-22 |

150 |

180 |

25 |

1450 |

22 |

78 |

150-130-30-22 |

150 |

130 |

30 |

1450 |

22 |

78 |

150-180-30-30 |

150 |

180 |

30 |

1450 |

30 |

78 |

150-200-30-37 |

150 |

200 |

30 |

1450 |

37 |

73 |

200-300-7-11 |

200 |

300 |

7 |

980 |

11 |

66 |

200-250-11-15 |

200 |

250 |

11 |

1450 |

15 |

64 |

200-250-15-18.5 |

200 |

250 |

15 |

1450 |

18.5 |

73 |

200-400-10-22 |

200 |

400 |

10 |

1450 |

22 |

75 |

200-400-13-30 |

200 |

400 |

13 |

14501 |

30 |

76 |

200-300-15-22 |

200 |

300 |

15 |

1450 |

22 |

76 |

200-250-22-30 |

200 |

250 |

22 |

1450 |

30 |

71 |

200-350-25-37 |

200 |

350 |

25 |

1450 |

37 |

71 |

200-400-30-45 |

200 |

400 |

30 |

1450 |

45 |

74 |

model |

caliber |

internet traffic |

lift |

rotational speed |

power |

efficiency |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|

250-600-9-30 |

250 |

600 |

9 |

980 |

30 |

78 |

250-600-12-37 |

250 |

600 |

12 |

1450 |

37 |

76 |

250-600-15-45 |

250 |

600 |

15 |

1450 |

45 |

73 |

250-600-20-55 |

250 |

600 |

20 |

1450 |

55 |

73 |

250-600-25-75 |

250 |

600 |

25 |

1450 |

75 |

71 |

300-800-12-45 |

300 |

800 |

12 |

980 |

45 |

74 |

300-480-15-45 |

300 |

480 |

15 |

1450 |

45 |

66 |

300-800-15-55 |

300 |

800 |

15 |

1450 |

55 |

73 |

300-600-20-55 |

300 |

600 |

20 |

1450 |

55 |

73 |

300-800-20-75 |

300 |

800 |

20 |

1450 |

75 |

75 |

300-950-20-90 |

300 |

950 |

20 |

1450 |

90 |

76 |

300-1000-25-110 |

300 |

1000 |

25 |

1450 |

110 |

76 |

300-1100-10-55 |

300 |

1100 |

10 |

1450 |

55 |

73 |

350-1500-15-90 |

350 |

1500 |

15 |

740 |

90 |

87 |

350-1200-18-90 |

350 |

1200 |

18 |

980 |

90 |

85 |

350-1100-28-132 |

350 |

1100 |

28 |

980 |

132 |

84 |

350-1000-36-160 |

350 |

1000 |

36 |

980 |

160 |

84 |

400-1760-7.5-55 |

400 |

1760 |

7.5 |

980 |

55 |

83 |

400-1500-10-75 |

400 |

1500 |

10 |

980 |

75 |

86 |

400-2000-13-110 |

400 |

2000 |

13 |

980 |

110 |

84 |

400-2000-15-132 |

400 |

2000 |

15 |

980 |

132 |

83 |

400-1700-22-160 |

400 |

1700 |

22 |

980 |

160 |

83 |

400-1500-26-160 |

400 |

1500 |

26 |

980 |

160 |

84 |

model |

caliber |

internet traffic |

lift |

speed |

power |

efficiency |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|

400-1800-32-250 |

400 |

1800 |

32 |

980 |

250 |

82 |

500-2500-10-110 |

500 |

2500 |

10 |

740 |

110 |

85 |

500-2600-15-160 |

500 |

2600 |

15 |

740 |

160 |

84 |

500-2400-22-220 |

500 |

2400 |

22 |

740 |

220 |

85 |

500-2650-24-250 |

500 |

2650 |

24 |

740 |

250 |

85 |

Fault analysis and troubleshooting methods

Fault phenomenon |

Possible causes |

Troubleshooting |

||||||||||

Insufficient flow or no water output |

|

|

||||||||||

Unable to start |

|

|

||||||||||

Stator burnt out |

|

|

||||||||||

Excessive current |

|

|