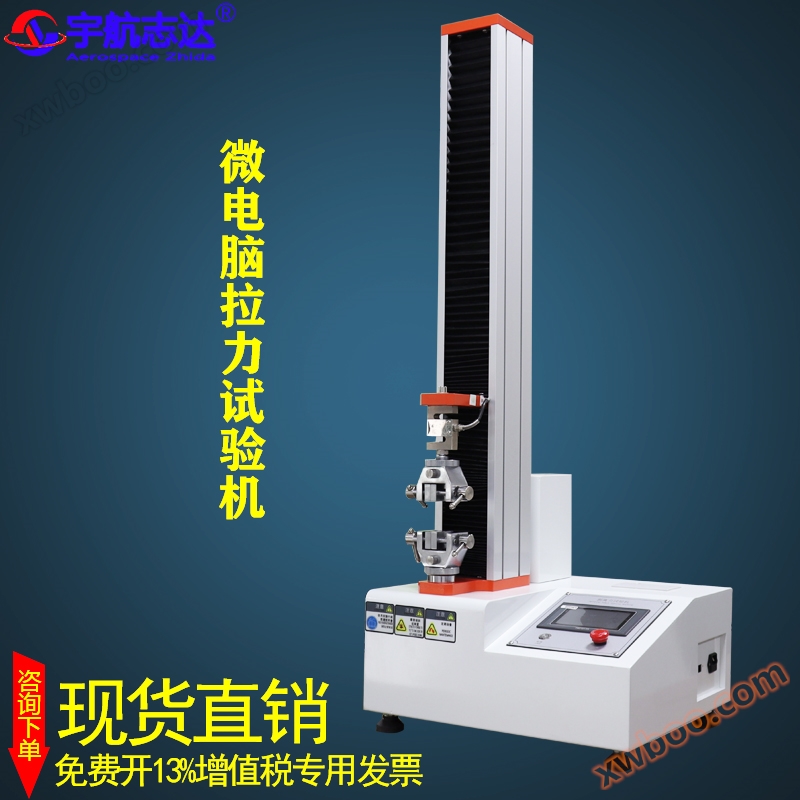

Luggage tensile testing machine, chassis tensile testing instrument, luggage tensile testing machine, manufacturer direct sales luggage tensile testing machine, testing instrument

The electronic tensile testing machine is suitable for tensile testing of materials such as rubber, plastic, textiles, waterproof materials, wires and cables, mesh ropes, metal wires, metal rods, metal plates, etc. It can also perform compression and bending tests with additional attachments. It has functions such as digital display of test force, continuous adjustable test speed, automatic shutdown of sample breakage, and peak value retention.

1. Instrument name: Electric single column electronic tensile testing machine;

2. Capacity: Choose within 100kg;

3. Units of strength: N, kgf, lbf;

4. Strength units: Pa, kPa, MPa, kgf/cm2, lbf/in2;

5. Test mode: fracture holding pressure, peeling, shear force;

6. Load decomposition degree: 1/100000;

7. Indication error: ± 1%;

8. Resolution: 0.1 N;

9. Effective travel: 450mm;

10. Test speed: 5-100 mm/min (knob adjustment);

11. Power system: speed regulating motor;

12. Transmission mechanism: ball screw (Taiwan Shangyin);

13. Dimensions: (L × W × H) 380 × 400 × 1000 mm;

14. Weight: Approximately 45 Kg.

Functions and features of electric single column electronic tensile testing machine:

1. Using a high-precision, fully digital speed control system and precision reducer, the precision screw pair is driven for testing, achieving a wide range of speed adjustment during the testing process with low noise and smooth operation.

2. The universal joint adopts a cross pin structure and has a swing angle limiting function. On the one hand, it is convenient for sample clamping, ensuring the concentricity of the test, and on the other hand, it effectively eliminates the influence of irregular samples on the sensor.

3. Touch key operation mode, real-time display on LCD monitor. The display interface can display the test method selection interface, test parameter selection interface, test operation and result display interface, and curve display interface, which is convenient and fast.

4. It can adjust the fast and slow lifting of the crossbeam during sample clamping, and has protective devices for overcurrent, overvoltage, overload, etc..

5. Optional microcomputer interface, which can be connected to an external microcomputer to control the experimental process and store and print data.