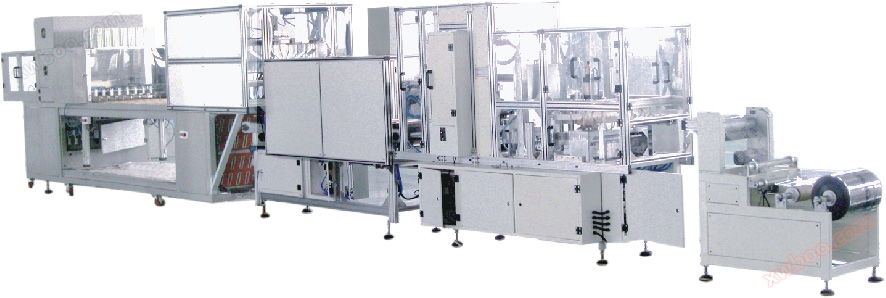

Vacuum forming, cutting, and sealing three in one blister packaging machine

Overview:

The vacuum forming, cutting, and sealing three in one packaging machine is a new generation of packaging equipment developed by our company's researchers through continuous improvement and independent innovation. Adopting the principle of hot pressing molding, PLC human-machine interface control, humanized, intelligent, stable performance, and simple operation. Automatic completion of bubble wrap forming, punching, automatic paper card loading, heat sealing and one-time forming, suitable for various specifications of paper plastic packaging. From the beginning of sheet material roll to the final product output, there is no longer a need for additional intermediate equipment, achieving a truly fully automated packaging assembly line and greatly improving production efficiency. Suitable for product packaging with vacuum sealing in industries such as stationery, batteries, cosmetics, hardware, and daily necessities.

Optional items:

1. According to different products, you can choose to design automatic products (such as dry batteries, lipstick, solid glue, etc.);

2. The heating method can be either upward or downward heating (choose one);

3. The robotic arm can be used for material retrieval, with the option of either translational or flipping;

4. Can specify the configuration brand and model;

5. Optional customized cutting conveyor belt.

Main technical parameters:

|

serial number |

project |

Technical Parameters |

|

1 |

Punching frequency |

10-50 times/minute |

|

2 |

molding area |

310×160(mm²) |

|

3 |

Vacuum suction traction stroke |

0~160mm |

|

4 |

Sealing efficiency |

4-8 seconds/module |

|

5 |

Sealing mold specifications |

500*175mm |

|

7 |

Total power |

8.5Kw |

|

9 |

Total weight |

About 3 tons |

|

10 |

Overall dimensions |

6000X770X1800 mm |