Software for metallographic and material analysis

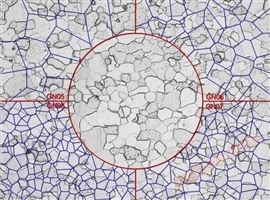

LAS X Grain Expert Software: Grain Analysis with Outstanding Accuracy and Reproducibility

The imaging environment provided by the LAS X grain expert module allows users to quicklyanalyzeStructures made of steel and other materials. A large number of structures and sample types can be studied using highly accurate edge detection algorithms.

In addition, the software module also includes traditional stereological methods such as Heyn linear intercept, Jeffries plane, and Abrams 3-cycle step. These methods will be automatically applied for directly calculating grain size. The traditional stereological method estimates grain size through one-dimensional methods, while LAS X grain experts directly measure grain area using specific two-dimensional algorithms. Compared with traditional non digital methods, this special method can achieve higher accuracy.

Software for metallographic and material analysis

LAS X grain experts cover multiple international standards for metallographic grain size analysis, such as ASTM E112, DIN/EN/ISO 643, GOST 5639, and JIS G0551. The main standards mentioned earlier also include derived or related standards, such as ASTM E1382 or ASTM E930, which only describe different technical methods used for grain size analysis.

LAS X phase expert software: can increase detection accuracy up to 250 times

The LAS X phase expert module facilitates advanced analysis of multiphase and microstructural components. It can automatically and accurately measure the area percentage of metals, minerals, and other materials.

Using high bit depth or HDR images, highly accurate detection algorithms facilitate the study of phase and display subtle differences in the acquired images. In traditional images, bit depth detection resolution is limited to 256 intensity levels, while LAS X phase experts can improve detection accuracy by more than 250 times.

The results calculated by software are usually calculated as the percentage of each phase in the observed microstructure. In addition to traditional phase analysis, the software also provides additional sample measurement capabilities and the ability to evaluate various other geometric and morphological parameters.

LAS X 2D analysis software: can adjust sample classification according to your specific needs

The LAS X 2D analysis module is developed specifically for combining high flexibility with precise sample and area measurements, while customizing automated analysis according to users' specific needs. Various samples and features, such as particles, powders, fibers, voids, porosity, etc., can be analyzed based on geometric and morphological characteristics as well as physical properties such as brightness or color.

The identified samples can be classified based on the available parameters in the LAS X 2D analysis module. This software is not limited to traditional methods, it also provides a programmable classifier that allows you to create custom parameters. You only need to click the mouse to select several samples of one or more classes, and the 2D analysis module can automatically determine all relevant parameters. Once a specific classifier is established, user interaction will be minimized in future analysis.

LAS X multi-channel analysis option allows for parallel operationDetection and classificationSample and provide a series of logical operators (AND, OR, XOR, etc.), allowing you to combine individual results to obtain multiple measurement combinations.

This powerful set of analysis capabilities makes the LAS X 2D analysis/multi-channel analysis module an ideal tool for performing multiple tasks in quality control and advanced research.

LAS X storyboard software: excellent ergonomics achieved through digital projection

Regarding measurement and analysis based on visual comparison, traditional eyepiece micrometers can cause eye fatigue and poor accuracy after prolonged use. The digital divider has made significant improvements in ergonomics and helps users maintain measurement accuracy over time. To record the analysis performed through the LAS X reticle, users can save them as electronic layers in each analysis image or region of interest.

The digital storyboard can directly project the features of interest onto the image displayed on the monitor. It can be switched by simply clicking the mouse without physically changing the optical components. In addition to providing a more enjoyable and time-saving working environment, the LAS X reticle module is also more cost-effective than traditional solutions. It does not require the purchase of a separate reticle or a combination of eyepiece and reticle. This application can provide over 50 digital reticle files, including specific solutions for phase analysis, grain size analysis, and non-metallic inclusion assessment that comply with various international standards. You can also edit digital storyboard files and use open-source drawing software to design other files.

LAS X Cast Iron Expert Software: Structural Analysis of Ductile Iron or Creep Graphite Iron

The LAS Cast Iron Expert Module provides a specific environment for rapid analysis of the microstructure of graphite in cast iron, such as ductile iron or ductile iron.

Unlike traditional methods based on comparison, LAS X cast iron experts automatically determine the type, shape, size, and distribution of graphite balls. The analysis performed using this module conforms to the procedures described in various international standards. In addition, the obtained results can also be expressed according to these same international standards (ASTM A247, ISO 945-2, JIS G 5502).

In addition to analyzing graphite spheres on etched samples, this software also helps determine the ratio of ferrite/pearlite. The detection algorithm of the LAS X cast iron expert module allows for fast parallel analysis of graphite, ferrite, and bead bodies using high-level deep or HDR images and advanced phase contrast observation methods. In addition, the software can also be used to evaluate various other geometric and morphological parameters.

LAS X Metallographic Toolbox: A Flexible and Easy to Use Tool for Stereoscopic Structural Analysis

The LAS X metallographic toolbox is an additional component that enhances the functionality of the LAS X 2D measurement module, making it a multifunctional toolbox for metallographic/metallurgical sample stereological analysis. In addition, it can also be transformed into a professional tool widely used in metallography and materials science.

It simplifies the manual tasks involved in defining calibration measurement parameters, such as baseline length, linear intercept, point counting, arc or multi-layer coating thickness.

It makes it possible to assign measurement values to different categories and compare and analyze relevant parameters. Therefore, it can generate results specific to components and phases.

LAS X Grain Expert Software: Grain Analysis with Outstanding Accuracy and Reproducibility

The imaging environment provided by the LAS X grain expert module allows users to quicklyanalyzeStructures made of steel and other materials. A large number of structures and sample types can be studied using highly accurate edge detection algorithms.

In addition, the software module also includes traditional stereological methods such as Heyn linear intercept, Jeffries plane, and Abrams 3-cycle step. These methods will be automatically applied for directly calculating grain size. The traditional stereological method estimates grain size through one-dimensional methods, while LAS X grain experts directly measure grain area using specific two-dimensional algorithms. Compared with traditional non digital methods, this special method can achieve higher accuracy.

LAS X grain experts cover multiple international standards for metallographic grain size analysis, such as ASTM E112, DIN/EN/ISO 643, GOST 5639, and JIS G0551. The main standards mentioned earlier also include derived or related standards, such as ASTM E1382 or ASTM E930, which only describe different technical methods used for grain size analysis.

LAS X phase expert software: can increase detection accuracy up to 250 times

The LAS X phase expert module facilitates advanced analysis of multiphase and microstructural components. It can automatically and accurately measure the area percentage of metals, minerals, and other materials.

Using high bit depth or HDR images, highly accurate detection algorithms facilitate the study of phase and display subtle differences in the acquired images. In traditional images, bit depth detection resolution is limited to 256 intensity levels, while LAS X phase experts can improve detection accuracy by more than 250 times.

The results calculated by software are usually calculated as the percentage of each phase in the observed microstructure. In addition to traditional phase analysis, the software also provides additional sample measurement capabilities and the ability to evaluate various other geometric and morphological parameters.

LAS X 2D analysis software: can adjust sample classification according to your specific needs

The LAS X 2D analysis module is developed specifically for combining high flexibility with precise sample and area measurements, while customizing automated analysis according to users' specific needs. Various samples and features, such as particles, powders, fibers, voids, porosity, etc., can be analyzed based on geometric and morphological characteristics as well as physical properties such as brightness or color.

The identified samples can be classified based on the available parameters in the LAS X 2D analysis module. This software is not limited to traditional methods, it also provides a programmable classifier that allows you to create custom parameters. You only need to click the mouse to select several samples of one or more classes, and the 2D analysis module can automatically determine all relevant parameters. Once a specific classifier is established, user interaction will be minimized in future analysis.

LAS X multi-channel analysis option allows for parallel operationDetection and classificationSample and provide a series of logical operators (AND, OR, XOR, etc.), allowing you to combine individual results to obtain multiple measurement combinations.

This powerful set of analysis capabilities makes the LAS X 2D analysis/multi-channel analysis module an ideal tool for performing multiple tasks in quality control and advanced research.

LAS X storyboard software: excellent ergonomics achieved through digital projection

Regarding measurement and analysis based on visual comparison, traditional eyepiece micrometers can cause eye fatigue and poor accuracy after prolonged use. The digital divider has made significant improvements in ergonomics and helps users maintain measurement accuracy over time. To record the analysis performed through the LAS X reticle, users can save them as electronic layers in each analysis image or region of interest.

The digital storyboard can directly project the features of interest onto the image displayed on the monitor. It can be switched by simply clicking the mouse without physically changing the optical components. In addition to providing a more enjoyable and time-saving working environment, the LAS X reticle module is also more cost-effective than traditional solutions. It does not require the purchase of a separate reticle or a combination of eyepiece and reticle. This application can provide over 50 digital reticle files, including specific solutions for phase analysis, grain size analysis, and non-metallic inclusion assessment that comply with various international standards. You can also edit digital storyboard files and use open-source drawing software to design other files.

LAS X Cast Iron Expert Software: Structural Analysis of Ductile Iron or Creep Graphite Iron

The LAS Cast Iron Expert Module provides a specific environment for rapid analysis of the microstructure of graphite in cast iron, such as ductile iron or ductile iron.

Unlike traditional methods based on comparison, LAS X cast iron experts automatically determine the type, shape, size, and distribution of graphite balls. The analysis performed using this module conforms to the procedures described in various international standards. In addition, the obtained results can also be expressed according to these same international standards (ASTM A247, ISO 945-2, JIS G 5502).

In addition to analyzing graphite spheres on etched samples, this software also helps determine the ratio of ferrite/pearlite. The detection algorithm of the LAS X cast iron expert module allows for fast parallel analysis of graphite, ferrite, and bead bodies using high-level deep or HDR images and advanced phase contrast observation methods. In addition, the software can also be used to evaluate various other geometric and morphological parameters.

LAS X Metallographic Toolbox: A Flexible and Easy to Use Tool for Stereoscopic Structural Analysis

The LAS X metallographic toolbox is an additional component that enhances the functionality of the LAS X 2D measurement module, making it a multifunctional toolbox for metallographic/metallurgical sample stereological analysis. In addition, it can also be transformed into a professional tool widely used in metallography and materials science.

It simplifies the manual tasks involved in defining calibration measurement parameters, such as baseline length, linear intercept, point counting, arc or multi-layer coating thickness.

It makes it possible to assign measurement values to different categories and compare and analyze relevant parameters. Therefore, it can generate results specific to components and phases.

LAS X Decarbonization Expert Module: Structural Analysis of Surface Carbon Consumption in Heat treated Steel

The LAS X decarburization expert module is a specific environment used to analyze carbon consumption caused by steel tempering or hot hardening. Carbon consumption or decarburization can affect performance, which in turn affects the quality of tempered steel. LAS X decarburization experts analyze the depth of functional decarburization to ensure that the performance of raw materials is not affected at this depth.

Choosing advanced image preprocessing filters can also help users overcome artifacts from sample preparation and etching.

Advanced analysis algorithms automatically correlate the parameters provided by materials with product specifications and calculate the final result. The software works automatically, and the operator can interact with it at any time.

The LAS X decarburization expert software covers multiple international standards (ASTM 1077, DIN 50192, ISO/DIN/EN 3887, JIS G0558, etc.) used to determine the depth of decarburization in steel.