1、 Product Introduction

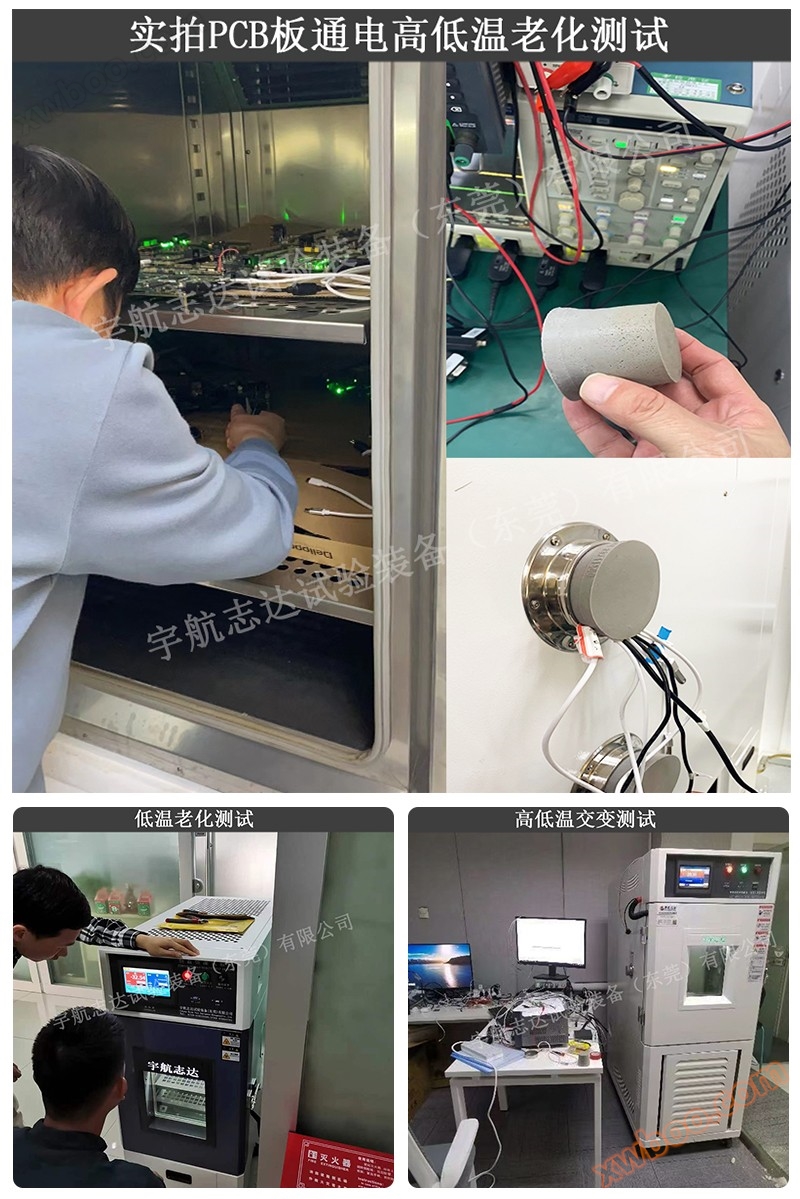

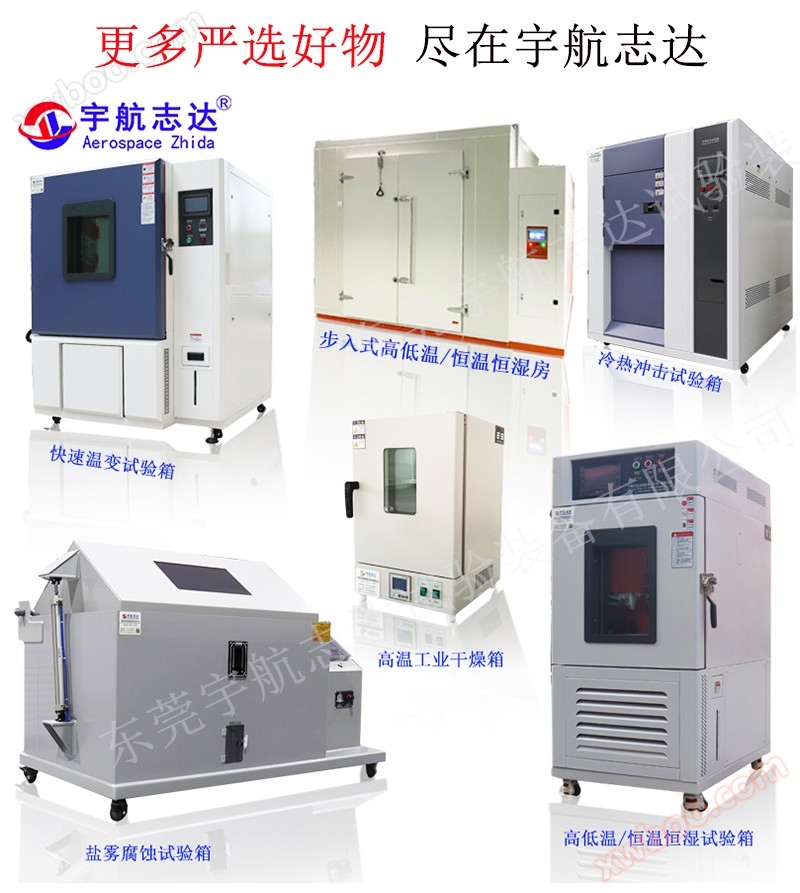

The constant temperature and humidity test chamber, also known as the environmental humidity chamber, tests the heat resistance, cold resistance, dry resistance, and moisture resistance of various materials. astronautics

Zhida High and Low Temperature Damp Heat Test Chamber is suitable for electronics, electrical appliances, communications, instruments, vehicles, plastic products, metals, food, etc

Used for quality testing of chemical, building materials, medical, aerospace and other products. High and low temperature wet heat test chamber is used to test products in high and low temperatures

Simulate operation in a warm and humid environment to evaluate the working quality of the product. Automatically through PID based on the set temperature point

The output of the operation is used to control the output of the heater, ultimately achieving a dynamic balance

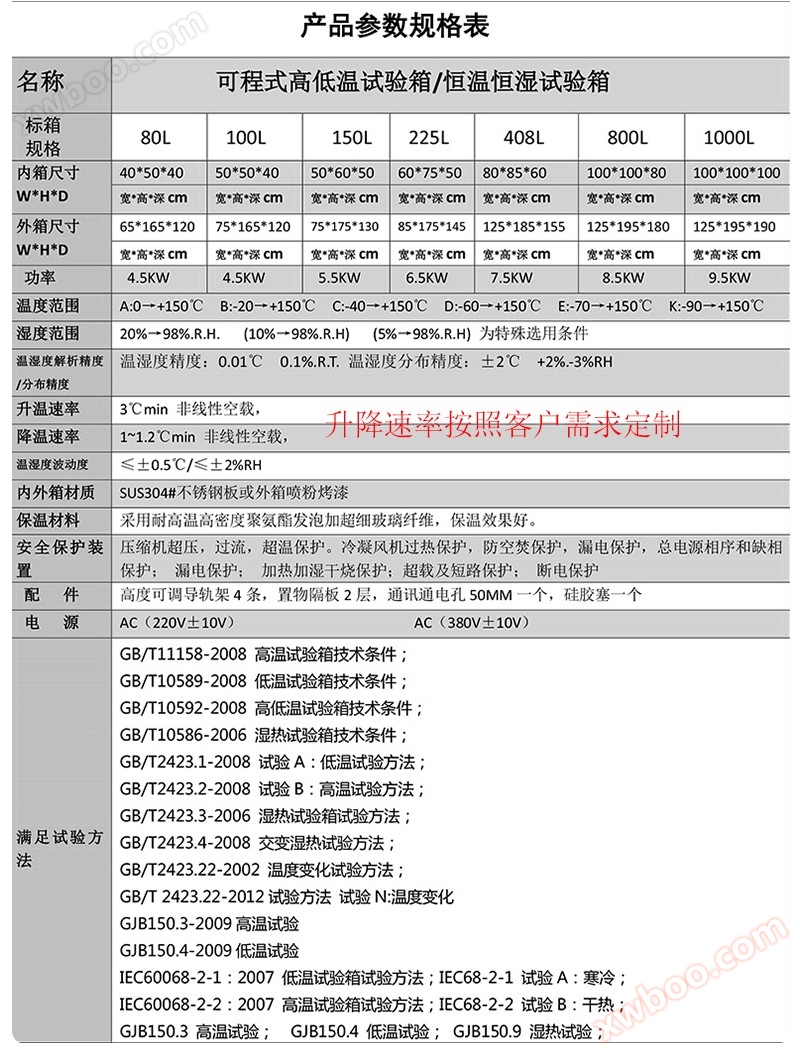

2、 Product specifications and models

Model Studio Dimensions External Dimensions

Y-HE-100 500×400×500 720×1600×1150

Y-HE-150 500×500×600 720×1650×1250

Y-HE-225 500×750×600 1060×997×1740

Y-HE-408 800×850×600 1182×1250×1880

Y-HE-800 800×1000×1000 1360×1500×1950

Y-HE-1000 1000×1000×1000 1485×1520×2020

3、 Main technical indicators

Temperature range -20 ℃, -40 ℃, -60 ℃, -70 ℃,~100 ℃ (150 ℃)

Humidity range 30-98% RH (can be customized according to customer requirements)

Temperature uniformity ≤± 2 ℃

Temperature fluctuation ≤ ± 0.5 ℃

Humidity deviation 2/-3% RH

Heating rate 2-3 ℃/min (can be customized according to customer requirements)

Cooling rate 0.7-1 ℃/min (can be customized according to customer requirements)

The ambient temperature for use is 25 ℃, with good ventilation

Power supply voltage AC220V/380V/50HZ

4、 Box structure:

The box is made of CNC equipment with advanced technology, smooth lines, and beautiful appearance

The material of the inner box is 1.2mm thick 304SUS stainless steel brushed plate, and the material of the outer box is 1.5mm thick A3 cold-rolled steel plate sprayed with plastic

The insulation material between the inner and outer boxes is ultra-fine glass fiber cotton, which has good insulation effect. The door frames between the inner and outer boxes are connected

Connected to a fiberglass frame, this connection has a good effect

4. Imported sealing materials and unique silicone sealing structure are used between the door and the door frame, which is sealed and has good aging resistance

The 5 door locks adopt the internationally popular light pressure lock, which improves the sealing performance of the box door

The air ducts inside the 6 boxes adopt a dual circulation system, consisting of two long axis axial flow fans, two stainless steel multi wing centrifugal fans, and a circulation system

Air duct composition, with uniform temperature inside the upper air outlet and lower air inlet box, increases high air flow rate, heating and cooling

The ability has greatly improved the temperature uniformity of the test chamber

7. The heater adopts a stainless steel ceramic strip electric heater, which heats up quickly and has a long service life

8) The middle of the box door is equipped with a large area of anti condensation tape conductive film insulated glass window and a high and low temperature resistant lighting device, which can clearly

Observing the experimental items inside the studio

External humidification system with solenoid valve controlling water inlet and liquid level switch controlling water level

The left side of the 10 box is equipped with a 50mm diameter test hole (customizable according to customer requirements), which can be used for external testing power lines or signals

Line usage

5、 Measurement and Control System

The temperature and humidity controller adopts a "TT-5166" large screen LCD display screen (7 inches), which is easy to operate and has RS-

232 communication interface, capable of remote control and software transmission, capable of designing programs on a computer and monitoring the entire testing process,

Save and print experimental data and curve diagrams.

Display resolution: 0.01 ℃

3 Operation modes: fixed value and program operation

4 Control mode: Continuous PID control

5 can be set with no less than 30 program curves, each curve set with no less than 800 steps, and no less than 6 can be connected at once

Program, capable of no less than 10 connections, with a single program capable of no less than 999 repeated experiments

6. Power failure recovery settings can be set, including: program termination after power failure, program continuous operation from power failure after power failure

7 can display the real-time running time, number of segments, remaining time, number of repetitions of the program, and can display experimental data, including settings

Fixed temperature, measured temperature and humidity, measured humidity, total operating time, segment operating time, remaining segment time, heating status

Calendar time, etc; Direct digital display of temperature

6、 Refrigeration system

1) The refrigeration unit adopts the French "Taikang" fully sealed environmentally friendly compressor

2) The refrigeration system adopts a unit or binary low-temperature circuit system design

3) Danish "Danfoss" thermal expansion valve, American "Aigo" drying filter; American "Aigo" solenoid valve

4) Refrigeration accessories: air-cooled coil condenser, finned multi-stage evaporator

5) The refrigerant used is imported environmentally friendly refrigerants R404A and R23

7、 Compliant with standards

1. GB/T2423.1-89 "Environmental Test Procedures for Electrical and Electronic Products" Test A: Low Temperature Test Method

2. GB/T2423.2-89 "Environmental Test Code for Electrical and Electronic Products" Test B: High Temperature Test Method

3. GB/T2423.4-93 "Environmental Test Code for Electrical and Electronic Products" Test Db: Alternating Damp Heat Test Method