Product Overview

Brand: Shandong Shenglong

Product Category: Pre Stretching, Standard Equipment

Product process: Overall spray coating

Production can be customized according to user size

Automatic pre stretching tray winding machineIntroduction:

Tray winding machineSuitable for container transportation of bulk goods and packaging of loose pallets. Widely used in industries such as glass products, hardware tools, electronic appliances, papermaking, ceramics, chemicals, food, beverages, building materials, etc. It can improve logistics efficiency, reduce losses during transportation, and has advantages such as dust prevention, moisture resistance, and reduced packaging costs. It is an ideal choice for improving product packaging quality.

product image Technical Documentation

1. Technical parameters Main technical parameters:

Packaging range: length 500-1200mm, width 500-1200mm, height L-shaped 2000mm

Packaging efficiency 20-40 pallets/hour

Rotary disc size diameter: 1650mm height: 77mm

Rotary table with a maximum load capacity of 2000kg and a thickness of 10mm (produced by Shandong Iron and Steel)

Rotary speed 0-12rpm/min

The total weight of the machine is 800kg

Dimensions L-shaped: 2650x1650x2480

Motor power turntable 0.75kw, membrane frame 0.4kw, column 0.4kw

Power supply single-phase 220V AC/50Hz/20A

Suitable for wrapping film for pre drawing machines with a thickness of 20-35 μ

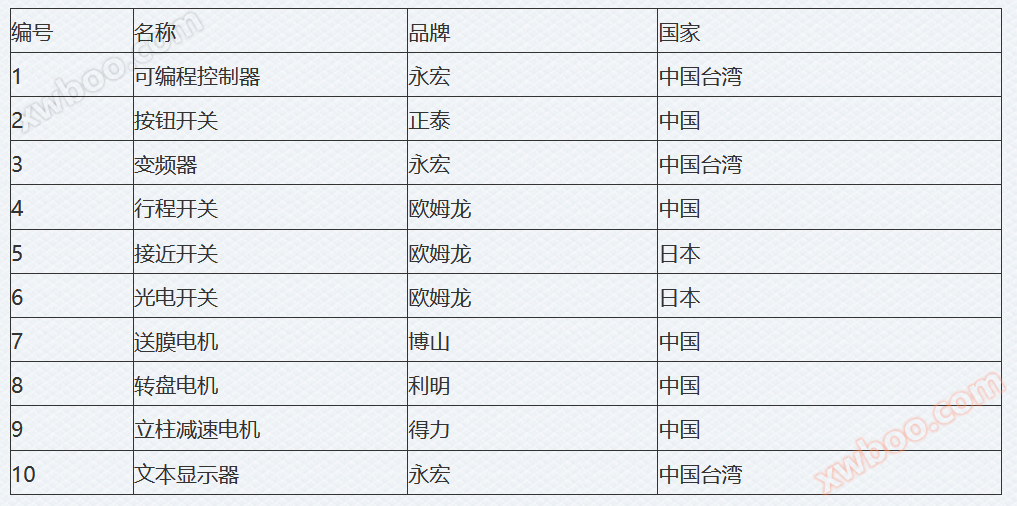

2. Control system

PLC programmable control for the operation of the entire machine, with adjustable winding layers and times ranging from 1-9 layers

The number of winding layers at the top and bottom can be set separately.

A separate reinforcement control button can be used to reinforce the local area at any position.

Humanized international panel icon, easier and simpler to operate

The photoelectric switch automatically senses the height of the goods, and the top crossing time can be set within 1-9 seconds.

Manual/automatic switching and reset buttons ensure that the equipment does not malfunction and affect its performance; Protect the safety of operators.

Mechanical and photoelectric switching functions allow for free and convenient operation of the equipment, achieving dual safety to ensure that the machine does not stop working in the event of minor equipment failures.

3. Rotary drive

Star shaped layout with wear-resistant new nylon support wheels for low-noise operation

Rotary table variable frequency speed regulation, slow start slow stop automatic reset

Separate origin reset button on the operation panel

4. Thin film system

Pre stretched automatic film supply (stretching ratio 250%), easy to pull out the film; Save 1/3 of consumables

Adopting a dual chain structure, the film frame can be raised and lowered at adjustable speeds, and the film feeding speed can be adjusted

(Shandong Shenglong Company: The columns are made of cold-rolled steel plates, with a thickness that fully meets national standards and is sturdy and durable. The guide rails use IPEX advanced technology and C-shaped guide rails.); It has bidirectional positioning, low noise, and reliable and durable stability in the rise and fall of the film frame, especially for the packaging of ultra-high goods. )

5. There are forklift slots in front and behind the equipment