1、 Product Overview

The ZTZL series rotary disc filter is a sewage deep filtration equipment independently developed and produced by our company. Its excellent design ensures reliable operation, simple operation, small footprint, large filtration surface area, and easy maintenance. The deep treatment process using microporous screens results in low turbidity and less total suspended solids in the treated water.

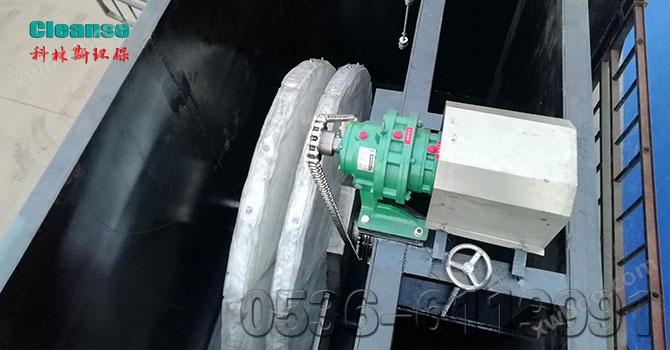

2、 Equipment pictures

The ZTZL rotary disc filter consists of a series of vertically installed, rotatable filter discs, which are mounted on the central drum. Each turntable consists of two semi-circular fan blades. Install a mesh stainless steel filter cloth membrane on the component, and the average pore size of the filter cloth can be selected from 5 μ m-200 μ m according to the actual requirements of the customer. The incoming water flows through a free fall and enters the filtering turntable from the central drum, passing through and filtering from the inside out. The filtered liquid then flows out from the outlet of the structure. During the filtering process, the turntable begins to be in a stationary state.

Solid substances in the inflow are intercepted by the filter cloth and deposited on it. As the filtration time increases, the liquid level of the central drum rises. When the preset maximum liquid level is reached, the turntable begins to slowly rotate, and the backwash water pump extracts filtered water through the flushing nozzle to flush the solid substances deposited on the filter cloth. Throughout the entire operation, filtration is continuous, even during the cleaning process. The flushed slag water mixture is discharged from the system through the slag discharge groove installed in the middle of the central drum.

4、 Specifications, models, and technical parameters

model |

Daily processing capacity (m³/d) |

Filter disk quantity |

Diameter (mm) |

power (kw) |

Internal dimensions of filter tank (L*W*H) |

CLZL/W2-5 |

5000 |

6 |

2000 |

3.1 |

3000×2600×3500 |

CLZL/W2-10 |

10000 |

10 |

2000 |

5.4 |

4400×2600×3500 |

CLZL/W2-15 |

15000 |

12 |

2000 |

5.8 |

5100×2600×3500 |

CLZL/W2-20 |

20000 |

16 |

2000 |

7.9 |

6500×2600×3500 |

CLZL/W3-30 |

30000 |

12 |

3000 |

9.4 |

5200×4000×4700 |

CLZL/W3-40 |

40000 |

16 |

3000 |

13.9 |

6600×4000×4700 |

CLZL/W3-50 |

50000 |

20 |

3000 |

18 |

8900×4000×4700 |

CLZL/N2-5 |

5000 |

6 |

2000 |

3.1 |

3000×2600×3500 |

CLZL/N2-10 |

10000 |

10 |

2000 |

5.4 |

4400×2600×3500 |

CLZL/N2-15 |

15000 |

12 |

2000 |

5.8 |

5100×2600×3500 |

CLZL/N2-20 |

20000 |

16 |

2000 |

7.9 |

6500×2600×3500 |

CLZL/N3=30 |

30000 |

12 |

3000 |

9.4 |

5200×4000×4700 |

CLZL/N3-40 |

40000 |

16 |

3000 |

13.9 |

6600×4000×4700 |

CLZL/N3-50 |

50000 |

20 |

3000 |

18 |

8900×4000×4700 |