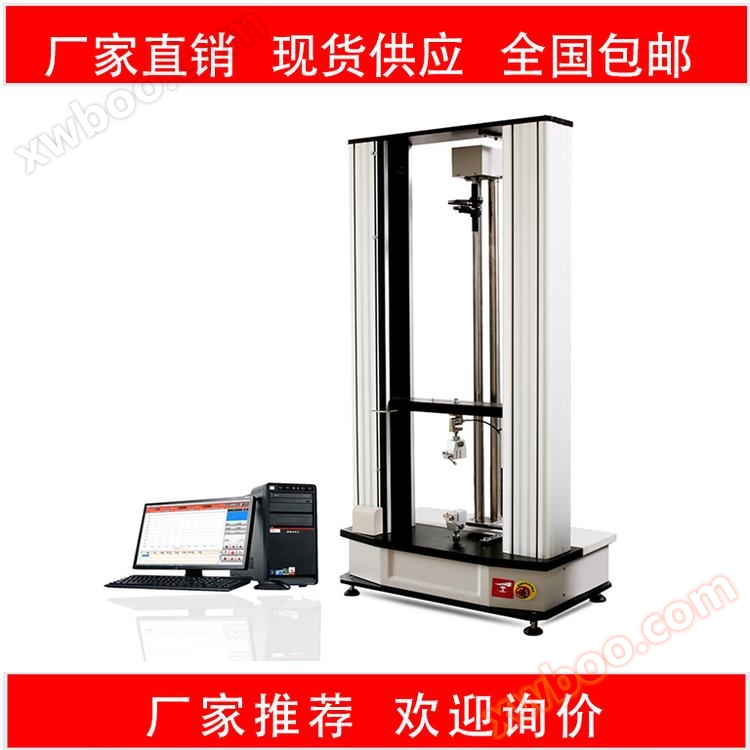

The CZ-4000D1 electronic testing machine is used for the determination of mechanical properties such as tensile, compressive, bending, shear, tearing, and peeling of various materials. This machine is a gantry style frame with a novel and elegant appearance. Computer digital speed control system, equipped with force sensors and automatic elongation tracking device, with good stability. Electrical appliances use PCs and interface circuit boards for data collection, storage, processing, and printing of test results, which can calculate basic physical performance parameters of materials such as force, yield force, average peel force, deformation, etc. During the experiment, the microcomputer collects real-time force values and deformation signals, and the software displays the "force displacement" curve. After the experiment is completed, the parameters are automatically calculated, saved, and the user can print out the required report format.

1、 Main technical parameters

1. Force range: 0-5000N Force resolution: 0.01N

System accuracy: less than ± 0.3%

3 speed range: 0.1-500mm/min (servo system)

4. Elongation tracking error: ± 0.5%

5 Power supply voltage: AC220V ± 10% 50Hz

6 Dimensions (length x width x height): 670 x 600 x 1560

Net weight: 210KG

II Characteristics of testing machine

1. Automatic reset: After the computer controls the test instruction, the system automatically resets;

2. High intelligence: After the experiment is completed, it automatically identifies the fracture

3 Multifunctional: By changing different fixtures, different experiments can be conducted;

4. Automatic gear shifting: Switch between different levels according to the size of the load;

5. Change speed: The test speed can be changed arbitrarily

6 Control methods: Test methods such as test force, test speed, displacement, strain, etc. can be selected.

Function 7: Record test data throughout the entire process. Provide functions such as saving, comparing, and tracking services. You can use the mouse to freely find the force values and deformation data of the test curve point by point for analysis, and can zoom in and compare locally.

8 Multiple protections: with automatic limit and overload automatic protection functions.

9 Automatic calculation: Automatically calculate various test results and can modify the report arbitrarily

10 Automatic Length Measurement: Equipped with a high-precision encoder, it automatically measures displacement stroke and elongation between marks.

11 High Taste: Exquisite craftsmanship, smooth lines, coupled with high-precision software and hardware technology and integration capabilities, fully reflecting exquisite manufacturing techniques and agile strength.

III Basic Configuration

1. Longmen double column mainframe.

2. One high-precision force sensor

3. High precision photoelectric automatic

4. The testing machine software has functions such as automatic calculation, storage, and comparison

5. Taiwanese brand gear reducer integrated motor

6. High precision ball screw

7. Synchronous belt wheel drive, no noise, no vibration, smooth operation

8. One set of specialized test fixtures