PC, PMMA, PET plastic sheet equipment

PC, PMMA, PET plastic sheet equipment

1. Detailed product description

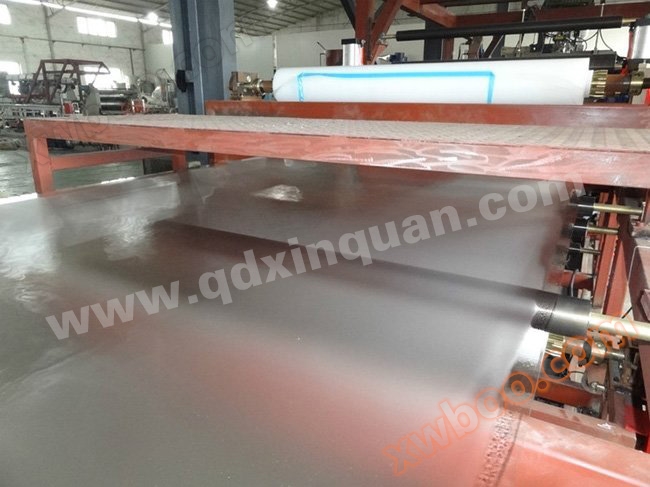

The PET transparent board production line is designed for APET, PET single-layer or multi-layer boards, and PS, PP, PE boards can also be produced on the same line. It is a multi-purpose machine.

PET sheets (APET, PETG, CPET) have excellent processability, transparency, barrier properties, and are non-toxic, odorless, environmentally friendly, and easy to recycle. In terms of food packaging, it is a material that replaces PVC.

This equipment fully absorbs and digests extrusion technology, and the products selected for the main components (such as screws, barrels, rollers, etc.), as well as the energy consumption, intelligence, automation indicators, safety standards, and process standards of the complete equipment, have all met the quality standards of the product. This series of products has multiple invention and utility model patents, which can replace imported equipment but have cost-effectiveness advantages.

The products produced are widely used in various industrial and civilian industries such as optics, home appliances, construction engineering, decoration, furniture, advertising, handicrafts, etc. The quality has reached the performance of the product, and we have a team of expert process engineers who match it to help users debug and produce high-quality products that meet the technical requirements of daily production!

3. Technical parameters:| PET, APET | PMMA, PC | ||||

| Main extruder diameter | 120mm | 130mm | 75mm (twin-screw) | 120 | 130 |

| Main extruder length to diameter ratio | 33:1 | 33:1 | 44:1 | 36:1 | 36:1 |

| Main extruder drive | 160kw | 200kw | 160kw-250kw | 185kw | 250kw |

| Co extruder diameter | 65mm | 75mm | 65mm or 75mm | 45mm | 45mm |

| Co extruded long diameter ratio | 33:1 | 33:1 | 33:1 | 30:1 | 30:1 |

| Co extruder drive | 37kw | 45kw | 37kw or 45kw | 22KW | 22KW |

| Sheet thickness | 0.15mm-1.2mm | 0.8-8mm | 1.5-10mm | ||

| Sheet width | 560mm-1500mm | 1000-1560mm | 1220-2100mm | ||

| Maximum extrusion capacity | 350kg/h | 500kg/h | 350kg/h-800kg/h | 420kg/h | 600kg/h |

| Installed power | 250kw | 320kw | 200kw-400kw | 180kw | 250kw |