summary:

Widely used in industrial safety chain systemsMPSS non-contact magnetic safety switch,Adopting a stainless steel shell, the product itself comes with fault monitoring and status indication functions, and provides humanized diagnostic functions through additional signal contacts. Our company can customize magnetic safety switches with special requirements for customers, such as installation in potential explosive areas, electrical wiring methods and wire lengths, housing materials, etc.

Key Features:

lHas excellent impact and vibration resistance, suitable for harsh application environments.

lThe stainless steel shell is sturdy and durable, suitable for occasions with heavy dirt and particularly strict cleaning requirements. (Engineering plastic material optional)

lHas good resistance to high and low temperature environments. No mechanical wear and tear, long service life.

lstainless steelSS316L shell, with a protection level of IP69K; The series protection level reaches IP65, IP67, IP69K.

lThrough additional signal contacts and its own status indicator lights, fault monitoring is carried out to provide humanized diagnosis.

lSquare or circular design, compact and simple, ultra-thin thickness only12.5mm, Save installation space, facilitate quick installation, and integrate connectors and cables for flexible installation.

lWorking distance reachable10~24mm。

lcomply withPL e of EN ISO 13849-1 and SIL CL 3 safety level of EN/IEC 62061.

lComplies with international standardsThe relevant content of EN 60947-5-3 standard and coded interlocking devices in accordance with ISO 14119.

lobtainCE certification.

Product Code |

|

working distance |

15-20mm 或12~24mm |

shell |

Stainless steel (aluminum alloy, or engineering plastic shell optional) |

power supply voltage |

24V DC +10% / -15% |

Protection level |

IP69K |

ambient temperature |

-70 ℃ to 60 ℃ |

High humidity |

Relative humidity of 50% at 70 ℃ |

Impact (EN60068-2-27) |

10g, 11ms |

Vibration (EN60068-2-6) |

10-55Hz, Vibration amplitude of 1mm, 5-minute scanning cycle |

High operating frequency |

7200 times per minute |

encapsulation |

epoxy resin |

LED status indication | |

green |

The actuator is within the detection range |

red |

The actuator leaves the detection range |

amber |

Fault prompt |

technical indicators

Main applications

1.Used for industrial equipment safety interlock systemSafety doors and position monitoring, top cover and valve protection, or for general important position monitoring or protective device monitoring,Like injection molding machines, machining centers.

2.Specially suitable for door fixators, covers, replicas, rolling doors, safety doors in industries or places such as food and pharmaceuticals, beverages, cosmetics, semiconductor chips, key laboratories, and experimental measurement.

3.Aircraft cockpit door monitoring, landing gear retraction locking and position indication, landing gear door and retraction control.

4.Crane safety interlock system control.

5.Control and monitoring of marine ship door systems.

6.Public transportation equipment door cover safety monitoring. Such as high-speed rail carriage door monitoring,Smart tram carriage door monitoring.

Standards and safety levels | |

International safety standards |

IEC 60947-5-3: 2013 |

EN ISO 13849-1: 2008 | |

EN62061:2005/A1: 2012 | |

ISO 14119:2013 | |

security level |

EN ISO13849 PLe/Cat 4, |

EN62061 SIL 3 | |

EN ISO14119 Type 4 Interlocking Device | |

mean time between failures |

tall |

Average diagnostic coverage rate |

tall |

Safety failure ratio |

99% |

Product standard model and code | |

MPSS-2015-S--150M |

Sensors and actuators (including 15cm M12 quick connect cable) |

MPSS-2012-P-2000 |

Sensors and actuators (including 2-meter self connecting cable) |

Product photos and dimensions

LED indication status description

LED indicator |

Expected cause of malfunction |

Measurement and inspection |

Lamp red |

Drive away from |

Move the drive close to the sensor |

There is an iron block between the driver and the sensor |

Remove the iron block between the driver and sensor |

|

24V input to pin 2 (power cord connected incorrectly) without dynamic signal |

||

Turn off the light |

No power supply or defective sensor |

Detect the positive terminals 24V and 0V of the power supply or replace the sensor |

Green light (no dynamic output detection) |

Input sensor dynamic signal missing |

Before detecting dynamic inputs or sensors |

Flashing lights (red, green) |

No dynamic signal input (driver and sensor in appropriate position) or output terminal connected to "0" V |

Output PIN5 and fix the detection sensor to activate it |

Dim lights or simultaneous red and green lights |

The driver and sensor are not in parallel or the actuator has entered the fault area |

Move the drive away from the sensor |

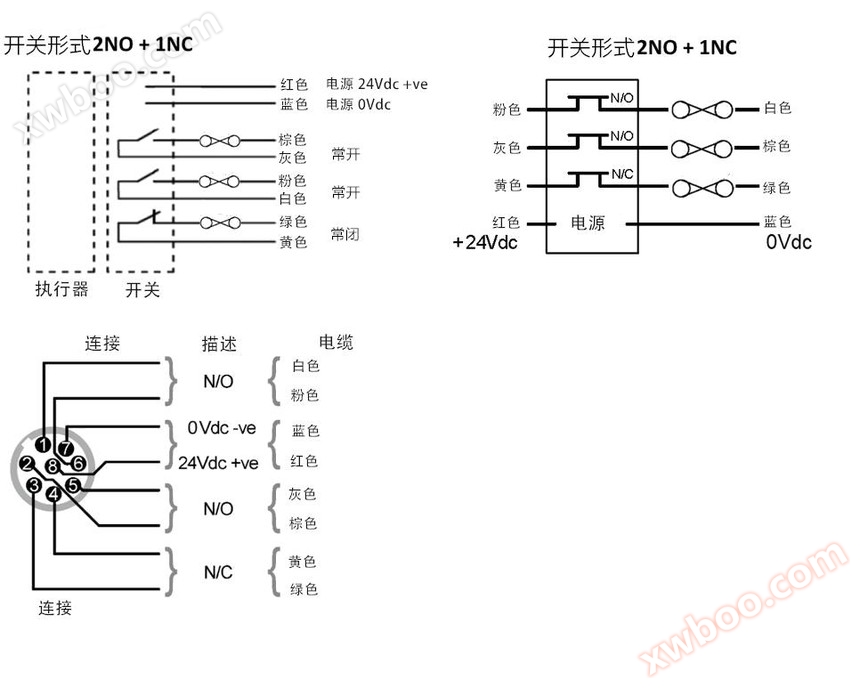

Electrical connection diagram

Installation diagram of safety switch

Recommended circuit diagram for safety switch application cases