Jilin Amino Acid Liquid Fertilizer Production Equipment Jilin Amino Acid Liquid Water soluble Fertilizer Production Equipment

Jilin Amino Acid Liquid Fertilizer Production EquipmentProduct Features

1. The original solution is filtered through a filter to remove impurities.

2. Automatic batching system to meet customer needs

3. Reaction kettle reaction, heating, cooling and stirring various raw materials through the reaction kettle. Form a liquid water-soluble fertilizer.

4. Emulsify the liquid in the reaction kettle to achieve uniform liquid without particles or precipitation

5. Then put the liquid into the liquid storage tank.

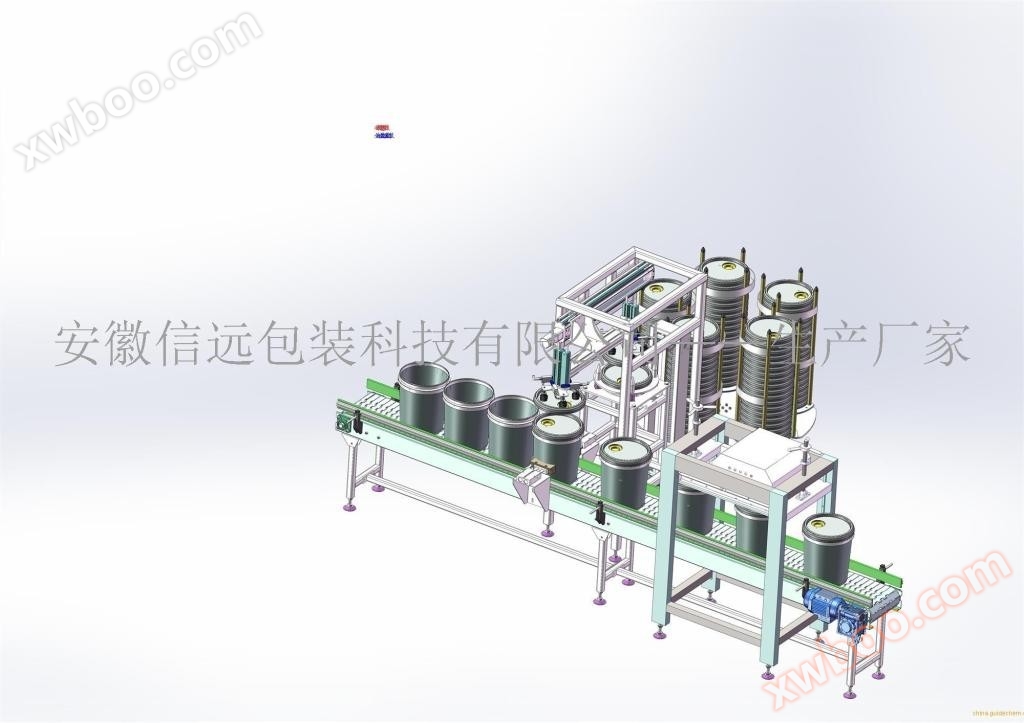

6. There are large barrel filling and small bottle filling production lines for filling.

7. Automatic packing line

8. Automatic palletizing line

Jilin amino acid liquid water-soluble fertilizer production equipmentProcess flow:

Bucket filling line: bottle sorting - filling - capping - labeling - sealing and coding - unpacking - packing - palletizing

Bag filling line: filling - packaging - finished product conveyor

Layout of production line construction:

Second floor: (Baocun storage floor, with only one person responsible for adding bottles, caps, and boxes to the group floor)

First floor (1 main packaging floor, with one person responsible for equipment operation and maintenance on the entire floor)

(Two finished product palletizing and temporary storage floors require one worker to be responsible for adding pallets and palletizing transportation)

Composition of production line equipment:

Second floor: Fully automatic box opening machine, box dropping machine, upper Yang platform, upper cover platform

First floor: Fully automatic bottle sorting machine, fully automatic filling machine, fully automatic capping machine, aluminum sealing machine

Positioning labeling machine, packing machine, fully automatic sealing machine, fully automatic robot palletizing machine, and main control electrical cabinet.

Performance characteristics:

1. Accurate measurement, smooth operation, wide adjustment range, and fast speed

2. Integrated and intelligent packaging

3. Significantly reduced production personnel and labor intensity

4. Easy to operate, reducing packaging costs

5. Wide application range, small footprint

Anhui Xinyuan has launched a complete set of production equipment for liquid fertilizers since 2013, including processes such as automatic metering and batching, mixing and blending, sedimentation and filtration, and quantitative filling. In 2014, Xinyuan launched an environmental protection project to turn waste into treasure, turning biogas slurry into fertilizer and solving the problem of biogas slurry pollution.

The microbial fermentation process is mainly divided into 5 steps. 1. Liquid storage: After pre-treatment, the biogas slurry is sent to the raw material tank, and after storage, it is sent to the fermentation tank; 2. Inoculate fermentation, the biogas slurry enters the fermentation tank, inoculates specific beneficial organisms, and is thoroughly stirred and mixed. After the liquid stays in the fermentation tank, it is sent to the ingredient tank; 3. Nutrient ingredients need to be added to the biogas slurry according to strict process procedures to ensure that the quality of fertilizers meets national standards; 4. Store the liquid, add nutrients to the liquid and send it to the finished product tank. After storage, send it to the packaging tank; 5. Packaging, automatic filling of finished liquid fertilizers.

workflow

raw material- Reactor - Transfer pump - Double filter/grinding - Storage tank - Transfer pump - Filling machine - Capping/capping - Transfer

Performance Characteristics

1. The system adopts PLC automation program control, automatically proportioning according to the prescribed formula, greatly saving labor costs and waste caused by manual ingredient errors

2. The temperature and time of material boiling can be automatically controlled

3. The system equipment is equipped with a sewage discharge mechanism for easy cleaning after production

4. This machine is made of corrosion-resistant 304 stainless steel material, and special materials can be optionally equipped with 316 stainless steel

Main technical parameters

1. User interface: DN65 material inlet pressure<0.6Mpa;

2Outer diameter of canning head:ф 40mm;

3. Applicable bottleneck: minimum 140 * 200 * 320mm; * 260 * 290 * 500mm;

4. Filling range: 5-30kg;

5Measurement accuracy:± 0.2% (note: filling accuracy depends on the viscosity of the material and the continuity and stability of material supply);

6. Packing speed: ≤ 250 barrels per hour (5kg);

7. Gas source pressure: 0.6-0.7 megapascals;

8. Gas consumption: 120L/min;

9. Power supply:~380 volts, 30 hertz

10. Total power: 1.6KW

11. Weight: approximately 1000kg;

12. Dimensions: 8700 * 1350 * 230mm (length * width * height)

Improving soil with weakly alkaline amino acids to supplement plant nutrition;

Features:

Strong parasitism: Imported microbial strains are used to competitively adsorb, entangle, and penetrate harmful bacteria, inhibiting the growth of pathogenic fungi in the soil and reducing their harm to plant roots.

Salt and stress resistance: Rich in seaweed extract biostimulants, it stimulates plants to produce emergency responses, promotes thickening of cell walls, promotes cell wall fibrosis, and reduces and blocks the harm of pathogenic microorganisms to plants.

Loosening soil and preserving nutrients: Supplementing soil organic matter (organic carbon) can significantly increase soil microbial activity, accelerate the decomposition of organic matter in the soil, increase soil temperature, improve soil particle structure, loosen soil and preserve nutrients, and improve fertilizer utilization efficiency.

Green leaf stability: Seaweed carbon bacteria complex enzyme supplements plant nutrition, stabilizes chloroplasts for long-lasting brightness, enhances the conversion ability of photosynthesis, and significantly increases yield.

Nutrients complete: Rich in various nutrients such as amino acids, large, medium, and trace elements required by crops, and multiple nutrients are integrated and present, with high absorption and utilization rates, balanced nutrition, and scientifically reasonable formulas, which can meet the nutritional requirements of crops at different stages.

Rooting and Strong Seedlings: It has a strong promoting effect on the growth of crop roots, causing seedlings to root quickly, have thick main roots, fewer floating roots, and more capillary roots. Enhance the ability of crops to absorb water and nutrients, and make the plants robust.

Blossoming and Polishing: Rich in 16 essential amino acids for plants, it can significantly improve fruit brightness. When used in combination with high potassium water-soluble fertilizers, it has a better effect and can significantly enlarge the fruit. The fruit surface has a good luster and a high selling price. It can be launched 7-15 days in advance.

Usage: Mix evenly and dilute 100-300 times, then apply with water or drip irrigation. Can be applied together with other fertilizers.