|

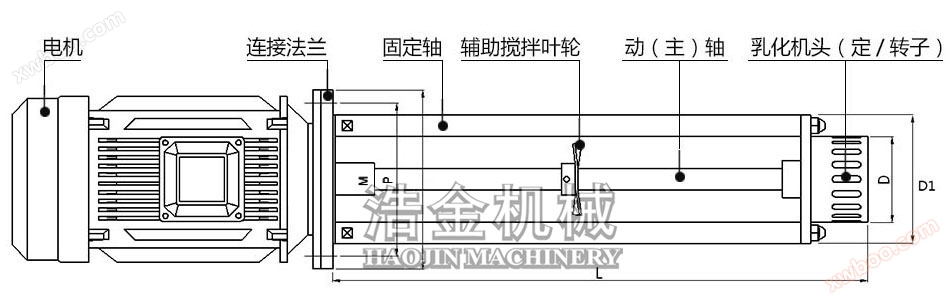

High shear (high shear emulsifier, high shear tank) is designed for mass production, using a claw type bite and bidirectional suction structure to avoid dead corners and vortex phenomena caused by difficult suction of upper materials. The shear force of the equipment is stronger, thereby improving production efficiency and dispersing emulsion quality.

Working principle of high shear emulsification:

High shear dispersion emulsification is the efficient, rapid, and uniform distribution of one or more phases into another continuous phase, where the phases are usually immiscible with each other. Due to the high tangential velocity generated by the high-speed rotation of the rotor and the strong kinetic energy brought by high-frequency mechanical effects, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tearing, and turbulence in the narrow gap between the stator and rotor. As a result, the immiscible solid phase, liquid phase, and gas phase are instantly uniformly and finely dispersed and emulsified under the joint action of corresponding mature processes and appropriate additives. After high-frequency cycling, stable high-quality products are finally obtained.

Intermittent high shear working process:

Under the centrifugal force generated by the high-speed rotating rotor, the material in the figure is simultaneously sucked into the working chamber from the upper and lower feeding areas of the working head in the axial direction.

The strong centrifugal force throws the material radially into the narrow and precise gap between the stator and rotor. Simultaneously subjected to centrifugal compression, impact and other forces, the material is initially dispersed and emulsified.

At the outer end of the rotating rotor, a linear velocity of at least 15m/s is generated, with a maximum of 40m/s, and strong mechanical and hydraulic shear, liquid layer friction, and impact tearing are formed, allowing the material to be fully dispersed, emulsified, homogenized, crushed, and ejected through the stator slot.

The material is continuously ejected from the radial direction at high speed, changing its flow direction under the resistance of the material itself and the container wall. At the same time, under the action of the upper and lower axial suction forces generated in the rotor area, two strong turbulent flows are formed, one above and one below. The material undergoes several cycles and finally completes the processes of dispersion, emulsification, and homogenization.

Dispersion processing technology:

Mixing: syrup, shampoo, detergent, fruit juice concentrate, yogurt, dessert, mixed dairy products, ink, porcelain glaze.

Dispersion mixing: dissolution of methyl cellulose, dissolution of colloids, dissolution of carbides, oil-water emulsification, pre mixing, seasoning production, stabilizer dissolution, smoke, salt, alumina, pesticides.

Dispersion: suspension, pill coating, drug depolymerization, paint dispersion, lipstick, vegetable soup, mustard mixture, catalyst, matting agent, metal, pigment, modified asphalt, preparation and depolymerization of nano materials.

Emulsification: lotion, ointment, cream, facial mask, face cream, emulsified essence, oil-water emulsification, emulsified asphalt, resin emulsification, wax emulsification, water-based polyurethane emulsification, pesticide.

Homogenization: medical lotion, ointment, cream, facial mask, face cream, tissue homogenate, dairy homogenization, juice, printing ink, jam.

|