PT100 thermistorWidely used in high-precision temperature equipment such as medical, electrical, industrial, temperature calculation, and resistance calculation. The WZ series PT100 thermistor, as a temperature measurement sensor, is usually used in conjunction with temperature transmitters, regulators, and display instruments to form a process control system. It is used to directly measure or control the temperature of liquid, steam, gas media, and solid surfaces within the range of -200 ℃ to -500 ℃ in various production processes.

Types of thermal resistors

1) Ordinary type thermistor

According to the temperature measurement principle of thermal resistance, the change in the measured temperature is directly measured by the change in the resistance value of the thermal resistance. Therefore, the change in resistance of various wires such as the lead wires of the thermal resistance body will have an impact on temperature measurement.

2) Armored thermistor

Armored thermistor is a solid body composed of temperature sensing elements (resistors), leads, insulation materials, and stainless steel sleeves. Its outer diameter is generally between 2 and 8mm, with a minimum of up to 8mm. Compared with ordinary thermistors, it has the following advantages: ① small size, no air gap inside, low measurement lag in terms of thermal inertia; ② Good mechanical performance, vibration resistance, and impact resistance; ③ Can bend, easy to install, and has a long service life.

3) End face thermistor

The end face thermistor temperature sensing element is made of specially processed resistance wire wound tightly against the end face of the thermometer. Compared with general axial resistance thermometers, it can more accurately and quickly reflect the actual temperature of the measured end face, and is suitable for measuring the end face temperature of bearing shells and other components.

4) Explosion proof thermistor

Explosion proof thermistor uses a special structure of junction box to confine the explosion of explosive mixed gas inside its shell caused by sparks or arcs within the junction box, so as not to cause excessive explosion in the production site. Explosion proof thermal resistors can be used for temperature measurement in areas with explosive hazards within Bla-B3c class zones.

Thermistor is a primary component that converts temperature changes into changes in resistance values. Typically, the resistance signal needs to be transmitted through leads to a computer control device or other primary instrument. Industrial thermal resistors are installed on the production site and there is a certain distance between them and the control room, so the leads of the thermal resistors will have a significant impact on the measurement results.

| Main technical parameters | |||||||||||||||||

| |||||||||||||||||

| Working principle | |||||||||||||||||

| Thermistor measures temperature by utilizing the characteristic that the resistance of a substance changes with temperature. The heated part (temperature sensing element) of a thermal resistor is uniformly wound around a skeleton made of insulating material with thin metal wires. When there is a temperature gradient in the measured medium, the measured temperature is the average temperature in the dielectric layer within the range of the temperature sensing element | |||||||||||||||||

| FEATURES | |||||||||||||||||

| National unified product design, universal interface size, and good interchangeability; | |||||||||||||||||

| Adopting an assembled structure, with good component disassembly and easy maintenance; | |||||||||||||||||

| Low cost of replacing vulnerable parts; | |||||||||||||||||

| Complete specifications, stable and reliable performance. | |||||||||||||||||

| Insulation resistance | |||||||||||||||||

| The insulation resistance at room temperature for assembling platinum thermistors should not be less than 100M Ω | |||||||||||||||||

| The insulation resistance at room temperature for assembling copper thermistors should not be less than 50M Ω | |||||||||||||||||

| The test voltage for insulation resistance at room temperature is 10-100V DC. | |||||||||||||||||

| Self heating effect: The platinum resistor allows a current of 5mA to pass through, resulting in a temperature rise of no more than 0.3 ℃. | |||||||||||||||||

| Thermal response time: When there is a step change in temperature, the time required for the output of the thermal resistor to change to 50% of the step change is called the thermal response time, represented by τ 0.5. | |||||||||||||||||

| Thermal resistance time constant | |||||||||||||||||

| |||||||||||||||||

| The nominal pressure of a thermal resistor generally refers to the static external pressure that the protective tube can withstand at operating temperature without breaking. | |||||||||||||||||

| The minimum insertion depth of the thermistor should not be less than 8-10 times the outer diameter of its protective sleeve. | |||||||||||||||||

| Insulation resistance: When the ambient air temperature is 15-35 ℃ and the relative humidity is less than 80%, the insulation resistance is 20 megohms (voltage 100V) | |||||||||||||||||

| The insulation resistance of the splash proof junction box should be 2 megohms (voltage 100V) | |||||||||||||||||

| The resistance value (R0) of the thermistor temperature sensing element at 0 ℃ and its ratio to the resistance value (R100) at 100 ℃: | |||||||||||||||||

| Ratio=R100/R | |||||||||||||||||

| When the division marks are Pt10 and Pt100; R100/R0=1.3850±0.001 | |||||||||||||||||

| When the division marks are Cu50 and Cu100; R100/R0=1.3850±0.002 |

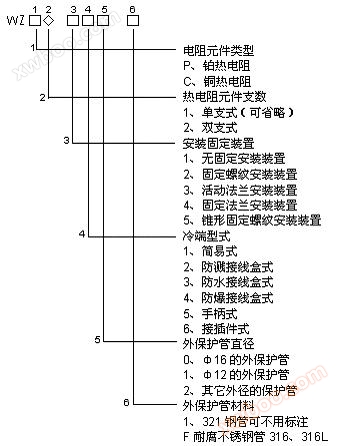

Selection of Thermistor