Tengzhou Zhongke Spectral Analysis Instrument Co., Ltd. is a professional manufacturer of gas chromatographs, liquid chromatographs, portable chromatographs, trace water analyzers, specialized equipment for power systems, and related chromatographic consumables (chromatographic injection pads, chromatographic columns, chromatographic injection needles, etc.). The equipment produced by the company meets national standards and is favored and recognized by users in the market. The following is a summary of the domestic GC2020Trace sulfur analyzerPrice/Domestic GC2020Trace sulfur analyzerDetailed analysis of manufacturers, usage methods, product features, and service advantages:

[Product Features]

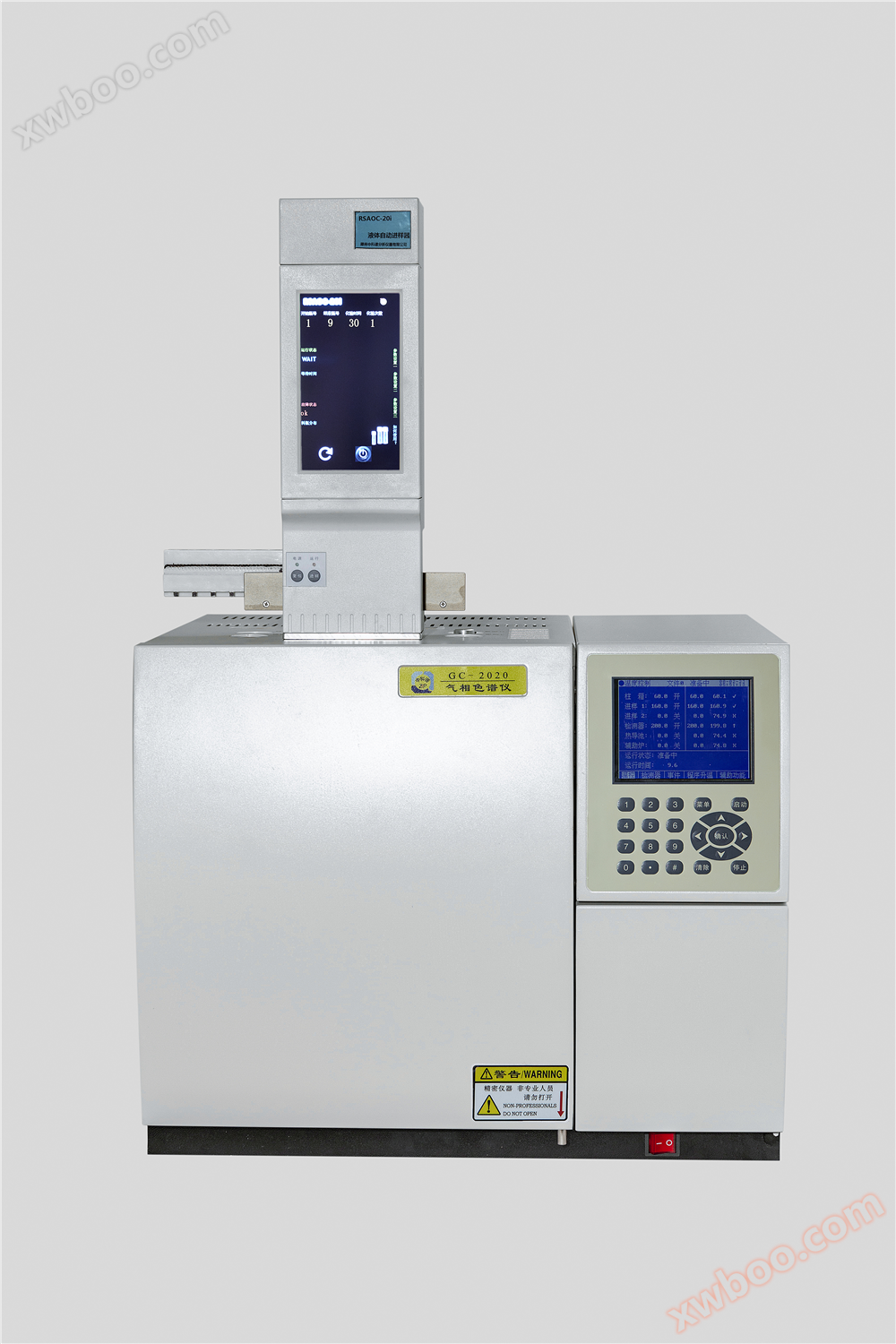

GC2020 is a specialized instrument with high sensitivity and selectivity for trace sulfur compounds. It has high sensitivity, good stability, easy operation, and Chinese liquid crystal display. It has been widely used in the determination of trace thiophene in domestic refined benzene projects.

[Product Application]

Sulfides are harmful components in petrochemical production, which can lead to reduced or even ineffective catalyst activity, decreased product yield, quality, and grade, as well as equipment corrosion and environmental pollution. Therefore, production enterprises not only need to correctly select reasonable desulfurization processes and desulfurizers based on the analysis results of sulfides, but also need to regularly detect the gas after fine desulfurization during the production process to avoid the occurrence of adverse consequences caused by excessive sulfur content as much as possible.

[Product Principle]

Specially designed for qualitative and quantitative analysis of trace sulfides in various gases such as methanol synthesis gas, ammonia synthesis gas, natural gas, coke oven gas, food grade CO2, tetrahydrothiophene, petrochemical industry, etc. The instrument uses a chromatographic column to separate various forms of sulfides, which are then detected by a flame photometric detector (FPD). FPD is a detector with high sensitivity and selectivity for sulfur compounds. The signal is amplified by a micro current amplifier and output to the chromatographic workstation, which automatically processes and displays or prints the analysis results (chromatographic peaks and sulfide content), accurately completing the analysis of trace sulfur.

[Instrument Configuration]

Model Function Applicable Object Detection Form

GC-2020 High Sensitivity FPD Detector Manual Injection Valve Natural gas, coal gas, coke oven gas form sulfur

High sensitivity FPD detector manual injection valve, food grade CO2 form sulfur

Chromatography Workstation Dual Channel Full Chinese Five Year Warranty

Chromatographic column for inorganic sulfur, imported diatomaceous earth Chromsorb (PTFE column)

Organic sulfur specific chromatographic column (PTFE column)

High purity nitrogen gas cylinder, high-purity oxygen gas cylinder, high-purity hydrogen gas cylinder, purity 99.999%

[Operating conditions]

Chromatographic analysis conditions

Chromatography column: ¢ 3mm * 3m PTFE column Gas chromatography: GC-2020 (Zhongkepu)

Column temperature: 60 ℃ Carrier gas: high-purity nitrogen

Flow rate: 20 ml/min (0.1Mpa) Injection volume: 1ml (six way valve injection)

Detector: FPD

[Precautions for Operation]

Some issues that should be noted when using are as follows:

(1) The hydrogen flame can only be ignited after the temperature of the FPD chimney section rises above 100 ℃ (about 1 hour), otherwise the detector will not be able to analyze the accumulated water.

(2) When aging a newly installed chromatographic column, the FPD should be disconnected from the column, otherwise solvent may enter the FPD and contaminate the detector, leading to a decrease in sensitivity.

(3) Do not open the detector cover with the high-voltage power switch turned on to avoid aging of the photomultiplier tube. The voltage divider resistor on the pin of the photomultiplier tube has been properly connected during assembly, and generally should not be tampered with.

(4) When turning on oxygen or air, slowly increase it from small to large, and do not turn it up all at once to avoid accidents.

(5) When shutting down, first turn off the oxygen, then turn off the hydrogen, and then turn off the "high pressure" and "column temperature" in sequence; After the testing room cools down to room temperature, turn off the "testing room"; After the greenhouse cools down to room temperature, turn off the "amplifier" and the "power" switch and carrier gas behind it.

(6) To avoid the situation where the temperature of the constant temperature chamber exceeds the maximum temperature allowed by the chromatographic column, otherwise it will lead to detector contamination, decreased sensitivity, chromatographic column deterioration, increased sulfide adsorption loss, and ultimately inability to analyze.

[Instrument Features]

1. Adopting a 320 x 240 dot matrix 5.7-inch ultra large LCD screen with Chinese/English display, real-time display of various temperatures and operating conditions, clear and intuitive content, truly realizing human-machine dialogue;

2. Power on self-test, automatic ignition, automatic temperature rise, wide range self diagnostic function, can accurately determine the fault location and alarm;

3. Six independent temperature control channels (vaporization chamber and capillary vaporization chamber can independently control temperature), with eight step programmed temperature rise function;

4. Overtemperature protection function: If any circuit exceeds the set temperature, the instrument will automatically power off and sound an alarm;

5. The unique vertical heating device makes sample vaporization more reliable, reducing the heat radiation generated by the vaporization chamber to the minimum and ensuring minimal temperature deviation inside the column box;

6. The intelligent fuzzy control rear door opening system automatically tracks temperature and dynamically adjusts it. The angle of the air door can achieve precise temperature control even near room temperature;

7. Configure a capillary split/non split injection device with membrane cleaning and filling column head injection, glass lined injection, and the ability to install gas injectors;

8. High precision dual stable gas path, capable of installing four types of detectors simultaneously;

9. Optional electronic flow pressure display system with built-in workstation device.

Technical indicators

Column box:

Temperature control range: Room temperature+5 ℃~399 ℃ (increments of 0.1 ℃)

◆ Number of ascending orders: Ten orders

◆ Lift rate: 0.1 ℃~50 ℃ (incremental 0.1 ℃)

◆ Cheng Sheng holding time: can be set by the user themselves

Sample injector:

◆ Up to 3 injection systems can be installed simultaneously

◆ Injection unit: Fill column injection system

Split/non split capillary injection system (with diaphragm cleaning function)

◆ Temperature control range: Room temperature+5 ℃~399 ℃

Comprehensive parameters

Dimensions: 490 × 460 × 480 [mm]; (Length x Height x Width).

Column box size: 260 x 250 x 150 mm; (length x height x depth).

Column installation interval size: 152.4mm; (6-inch standard interface).

Chromatography column: metal or glass column with an outer diameter of Φ 3 to Φ 5mm;

Instrument weight: 60 Kg

Parameters of flame photometric detector

⑴: Detection limit: 5x10-10 grams of sulfur per second or 2x10-10 grams of sulfur per second (calculated as H2S)

Zui small inspection measurement: 0.05ppm or 0.02ppm (calculated as H2S) 0.1ppm (calculated as SO2)

⑵: Baseline drift: ≤ 0.2mV/h;

⑶: Relative root mean square error: ≤ 10%;

⑷: Temperature of the constant temperature chamber: ± 2% higher than room temperature (8 ℃~120 ℃);