Accurate, fast, and portable

Application fields:

On site inspection and analysis of surface defects such as scratches, cracks, wear, scratches, pits, chiseling, corrosion, etc. on materials such as metals, composite materials, fabrics, etc;

Three dimensional inspection of step differences and concave convex amounts in riveting, welding, seams, etc; Measurement and analysis of three-dimensional surface roughness;

Measurement of geometric dimensions such as groove depth, arc, chamfer, etc;

Measuring principle:

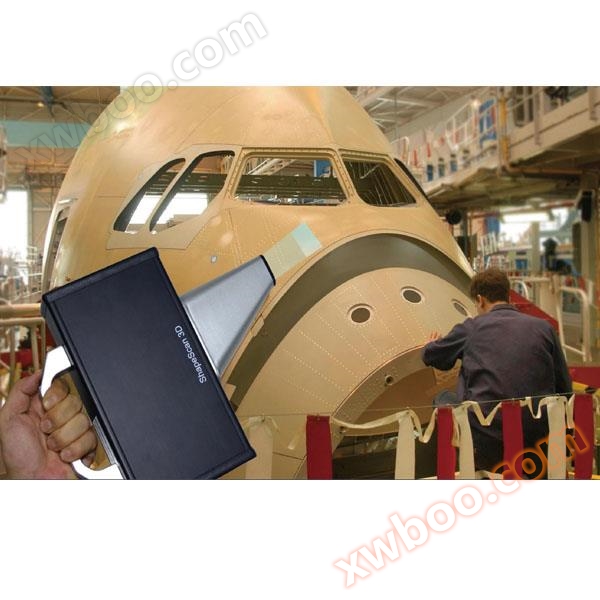

The portable 3D optical surface scratch measuring instrument developed by German GFM company based on laser stripe phase projection technology and DSP high-speed image processing chip is used for on-site surface quality characteristic detection. It has the advantages of fast measurement speed, accurate measurement, and portability.

Instrument features:

Portable on-site detection of surface scratches, defects, step differences, and other surface geometric characteristic parameters of large parts;

Three dimensional measurement of surface scratch defects, visually detecting the deepest part of the scratch defect through topological color difference maps;

Professional scratch measurement and analysis software, with multiple filtering methods including polynomial filtering, Gaussian filtering, mean filtering, etc., effectively eliminating the influence of factors such as surface contour, tilt, noise signals, burrs, dust, etc. on measurement results;

Design of high angle light path and blue LED light source, measurement is not affected by high reflective surfaces;

SDK software package, open instrument interface, can be developed again;

Instrument accessories