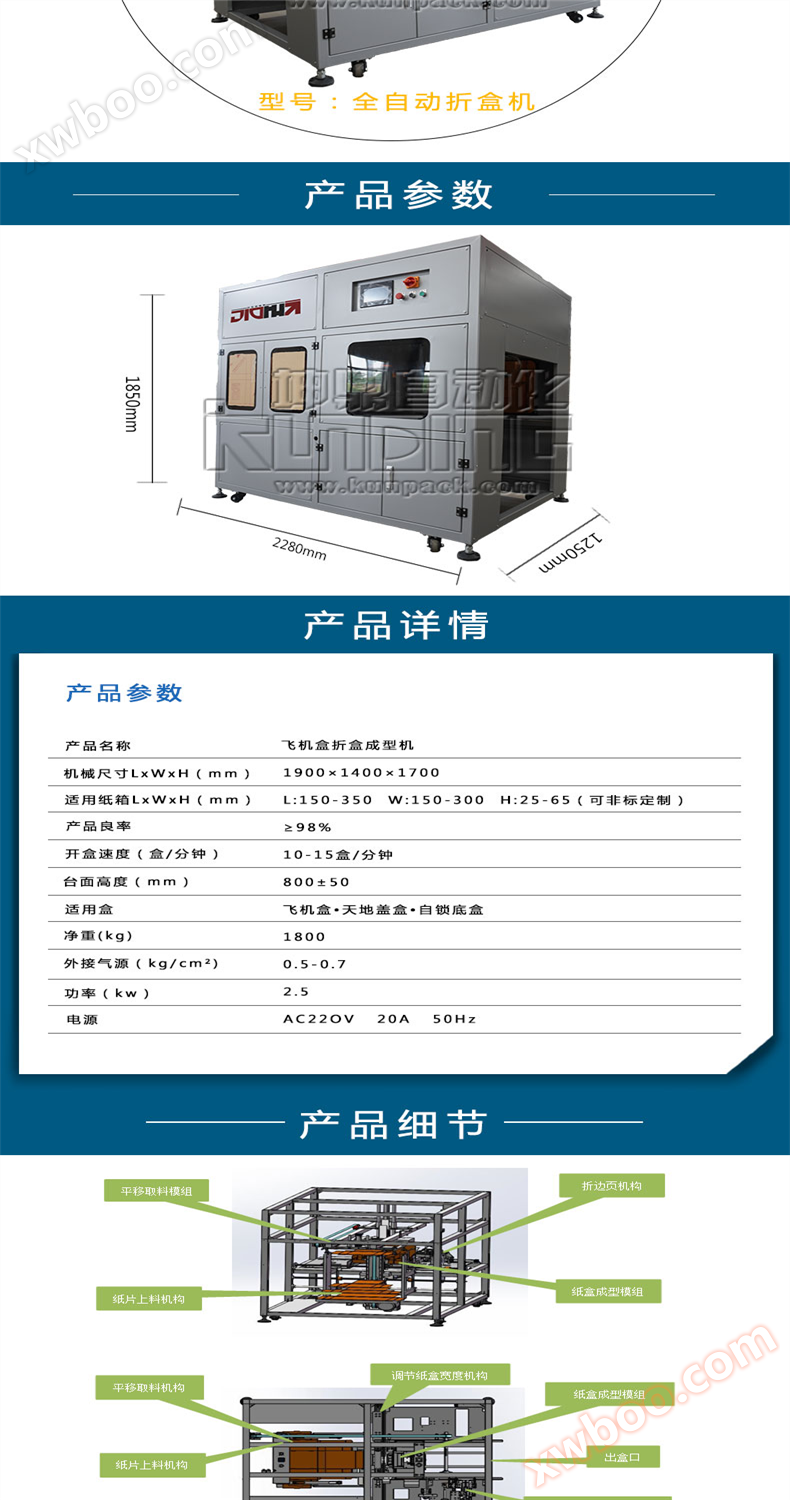

.The automatic airplane box folding machine consists of three parts: a seasoning bin, a pick-up/delivery/discharge, and an adjustable folding.

.Using suction cups and electric lifting to suck up the color box, it is transported to the next station and pushed out into shape through a cylinder.

.And fold from both sides of the cardboard box. After pre forming, when passing through each position, fold the bottom first, then fold the left and right side pages, so that the cardboard box is fully engaged and firmly connected.

.All mechanisms of the folding machine are reset, and the finished box discharge mechanism transports the finished paper boxes to the assembly line, and the above actions are automatically cycled.

.The use of PLC+human-machine interface control, with convenient operation, simple maintenance, and stable performance, is an essential assembly line equipment for automated large-scale production.

.Widely used in industries such as 3C electronics, food, medicine, tobacco, and daily chemical products.

.Imported accessories: Select imported parts, electrical components, and pneumatic components to ensure more stable equipment.High tech: With independent research and design experience, and the introduction of advanced technology from folding machines in the United States, Germany, and Japan

.Excellent quality: The mechanical performance is precise and durable, the structural design is rigorous, and the components have passed aging tests to ensure that every detail is more stable

.Easy to operate: Suitable for opening and forming paper boxes of various sizes. If you need to change the specifications of the paper box, you can manually adjust it. The operation is simple and convenient

.Safety performance: equipped with safety protection doors, making production safer and packaging more efficient