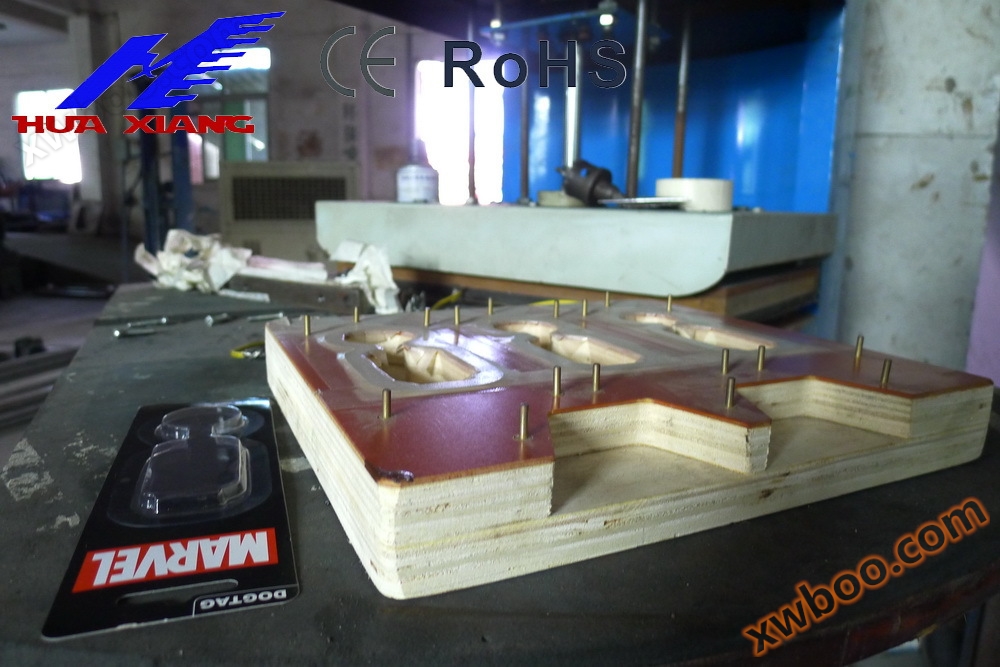

Product Introduction:

We use imported heating materials, Nissan high-temperature adhesive tape, and high-quality copper nails to make various electric wood molds, which have the characteristics of uniform heating and good sealing effect. They can be applied to various vacuum disc packaging machines and fully automatic chain machines, and are used for heat sealing packaging of paper cards and bubble shells.

Mold usage:

Used for packaging exquisite toys, stationery, daily necessities, cosmetics, industrial and hardware products, small tools, etc., sealed into beautiful transparent jackets, trying to make the packaged items show various advantages at a glance.

Sample: Paper card+vacuum formed, hot press sealed.

Electric wood modeling:

1. The materials used for the electric wood mold are 8407635, SKD61 materials, which require good quality and hardness at high temperatures.

2. Electric wood molds are prone to wear and tear, so they need to be heat treated to around HRC60, which means they need to have a hardness similar to that of cutting tools. Of course, if the quantity is not large, it is also feasible to use pre hardened steel of NAK80 type, around HRC40.

3. The area that is particularly prone to wear and tear is the glue entry point, so it is best to make the glue entry point into an inlay, such as white steel or black steel. Of course, Wugang is the best, but Wugang is fragile and can only be processed by wire cutting or grinding. Made into replaceable inserts for easy replacement after wear and tear.

4. As the mold needs to be heated, a heating tube or heating element must be added.

5. In order to prevent the heat from being carried away by the injection molding machine during heating, it is necessary to add insulation boards on both the upper and lower panels, which can be asbestos or electric wood boards.

6. As heating the mold will cause thermal expansion, in order to prevent the mold from getting stuck, the guide post and guide sleeve of the mold should be slightly looser than the plastic mold.

7. Electric wood molds are prone to sticking, so they should be made smooth and the surface of the mold cavity should be plated with hard chromium. The cut surface must not have any patterns, and if the top surface is large enough to be smooth, there can be some decorative patterns

8. The steel used for electric wood molds is different from that used for plastic molds. The upper and lower plates of the mold need to be covered with a layer of insulation board

9. Electric wood belongs to thermosetting materials The temperature of electric wood powder in the barrel is 100 degrees, at the gate it is 160 degrees, and inside the mold it is 180 degrees The electric wood injection mold needs to be heated to 160 degrees before injection molding, so a heating tube needs to be added

10. The steel used for the electric wood mold is similar to that of the plastic mold, with either 8407, S136 heat treatment, or SKD61 heat treatment. However, the most important thing is that the mold must be polished to 2000 # sandpaper and then plated with hard chromium to prevent sticking to the mold. The mold must be heated with a heating rod inside to produce the product.

Click on the link to learn moreMany: https://detail.1688.com/offer/.html?spm=a2615.7691456.0.0.917aca87W8ahf

Required equipment:

Electric wood molds are suitable for various vacuum disc packaging machines and fully automatic chain machines, and are used for heat sealing packaging of paper cards and foam shells.

Suitable packaging machines for all models of our company:

Our own mold production workshop meets all customized production requirements

Factory workshop