Main performance characteristics:

|Adopting servo technologyMotor andminuteComputer control system,ItalyTL50Photoelectric eye tracking and coordinated control, the host adoptsTaiwanThe frequency converter adjusts the speed to ensure smooth bag making and accurate sealing and cutting.

|Adopting a high-precision temperature controller for automatic temperature control, ensuring that films of different thicknesses are securely and aesthetically sealed.

|The feeding system adopts uniform feeding control, ensuring even and smooth feeding; The discharge conveying adoptshigh qualityConveyor belts andImportVariable frequency drive speed regulation ensures smooth and reliable bag operation.

|The hot cutting knife is forged from imported heat-resistant steelHigh temperature heatingwithouteasyDeformation, non stick knifeThe sealing roller is made of high-temperature resistant silicone material;

|The computer control system has functions such as automatic counting, cumulative counting, early alarm, pause, etc., automatic control of start and stop, and high degree of automation.

| The model is dual material and dual computercontrol system

|Roll up and split type, using semi-automatic paper tube without paper tube winding machine for dual-use,model,3Rubber roller drive,

|Adopting servo technologyControl,each side1Set up computer tracking

| Japanese Panasonic electric eye tracking with color tracking

| Used for front and rear feeding0.75AC motor with frequency converter,speed regulation

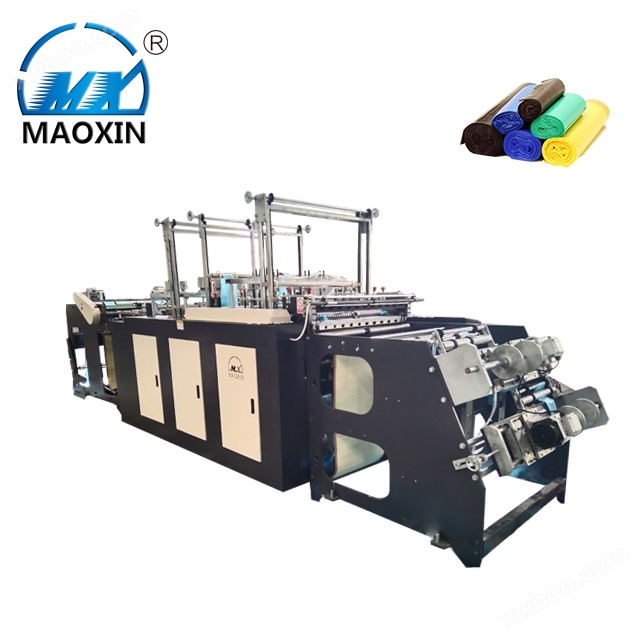

Finished product image:

Main technical parameters

|

model |

MXBZ-500 |

|

Maximum bag width(mm) |

400 |

|

Maximum bag making length(mm) |

100-1000 |

|

Bag thickness(mm) |

0.008-0.20 |

|

machine speed(pcs/min) |

100-130 |

|

Motor Power(kw) |

1.5 |

|

total power(kw) |

14 |

|

power supply(V) |

220 |

|

Mechanical dimensions(mm)L×W×H |

6000×1500×1800 |

|

Mechanical weight(T) |

2.3 |