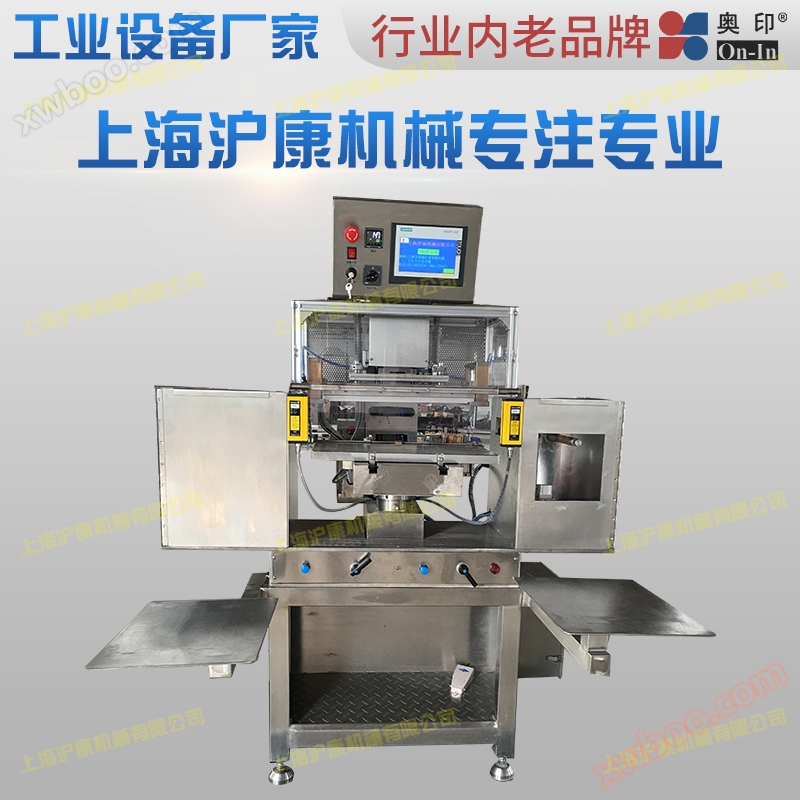

DH-400 hot stamping machine

Machine Overview:

Manual feeding: The bottom plate extends, and after the employee manually feeds, they step on the foot pedal switch to enter the bottom plate and start printing;

Printing: The printing template is pressed down and then hot printed.

Manual cutting: The film winding motor rolls away the waste film after hot pressing and sends it into the unpressed hot printing film. The bottom plate extends, and the employee will take out the inner bag that has been heat printed and start the next cycle

The printing process for disposable products suitable for the medical industry, especially on infusion bags and blood bags, occupies the main market in the industry

|

workbench: |

1(260X460)mm |

|

Extreme hot stamping size: |

200mm*400mm |

|

Stamping stroke : |

65mm |

|

workbench stroke: |

250mm |

|

Adjustment range of hot stamping time: |

0.01second~30second |

|

Total heating power: |

4000W |

|

Maximum speed of an empty aircraft: |

2.3Sec/bag (2L) |

|

Temperature regulation range: |

30 ºC~400ºC |

|

working pressure: |

20000N |

|

Pneumatic clamp device |

1set |

|

Pneumatic clamp front bag pressing device |

1set |

|

Pneumatic mold installation device |

1set |