HA8100

1. Overview of Project Proposal

According to the national standard《AQ3036 Specification for Setting up Safety Monitoring Equipment in Major Hazardous Chemical Tank Areas and GB50493 Design Specification for Combustible and Toxic Gas Detection and Alarm in Petrochemical Industry both require first determining the "main leakage and release sources" within the monitored area, and then according to the above two standards,The horizontal distance between the combustible gas detector and any release source within its coverage area should not be greater than10m, The horizontal distance between a toxic gas detector and any release source within its coverage area should not be greater than 4m. If the release source is located in a closed or partially poorly ventilated semi open factory building, the horizontal distance between a combustible gas detector and any release source within its coverage area should not be greater than 5m; the horizontal distance between a toxic gas detector and any release source within its coverage area should not be greater than 2m.

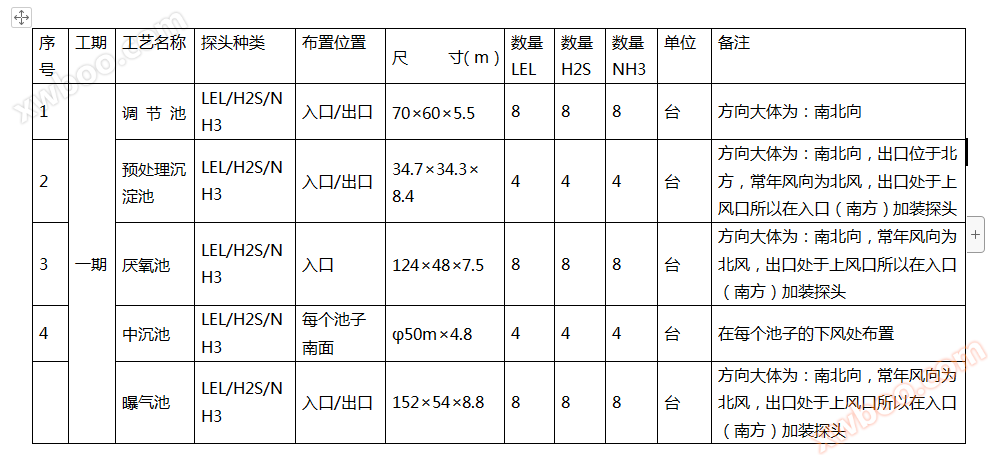

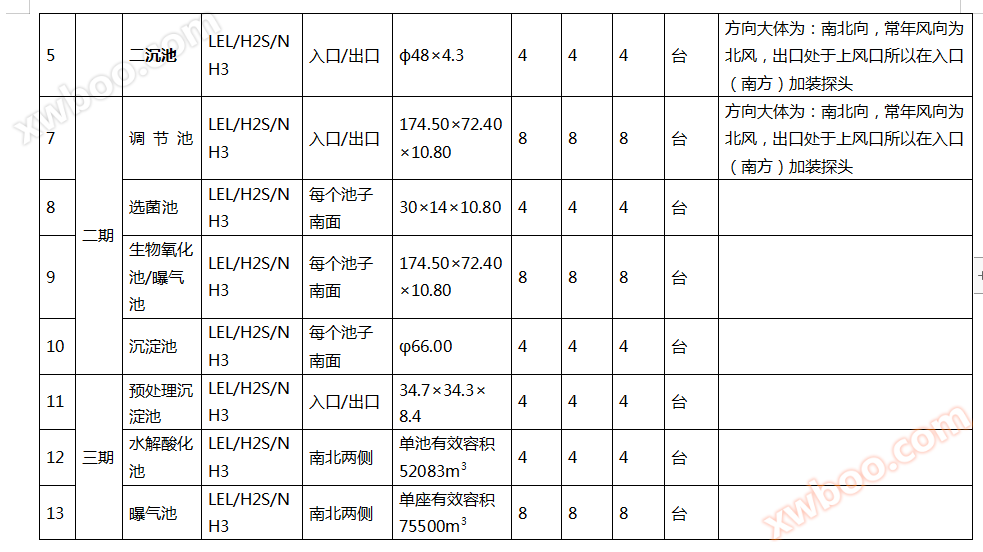

In the sewage treatment industry, the specific situation is different from the above. Based on our experience, most of the hazardous gases come from the volatilization of treated sewage or the generation during the treatment process. Therefore, fixed gas detectors should be arranged with each treatment tank as the release source carrier.

1.1 General principles for the layout of probes in sewage treatment plants:

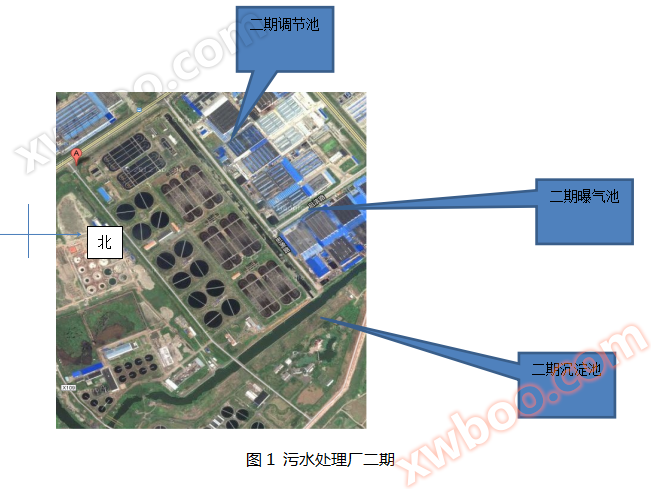

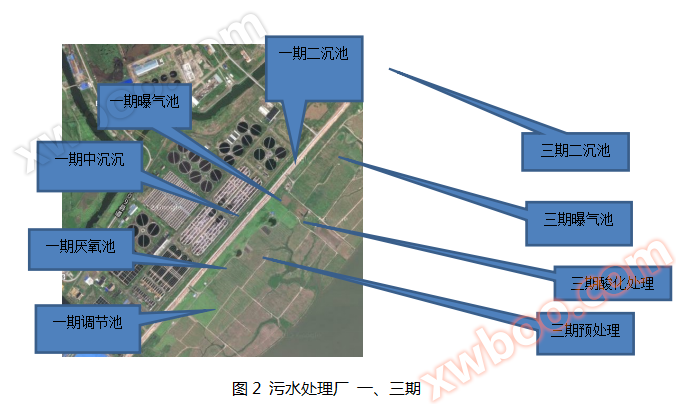

1.1.1XX Water Treatment Development Co., Ltd. is located in the northeast of XX City, within the Binhai Industrial Zone of XX County. It borders the Cao'e River to the east and the Qiantang River to the north, and is approximately 20 kilometers away from the city center of XX.According to the annual monitoring areanorthCharacteristics of WindOn the south side of each monitoring area, corresponding gas monitoring probes are arranged on the east and west sides.

1.1.2According to the commonly used monitoring gas types in sewage treatment plants, they are: combustible gasH2S and NH3, it is recommended to install VOC detectors to detect organic volatile compounds. Therefore, the same combustible gas, H2S, and NH3 probes are installed at each monitoring point.

1.1.3The selection and arrangement of other types of toxic, harmful, and flammable gases shall be based on the different types of gases generated in each process, and shall comply with the requirementsThe general principle arrangement of 1.1.

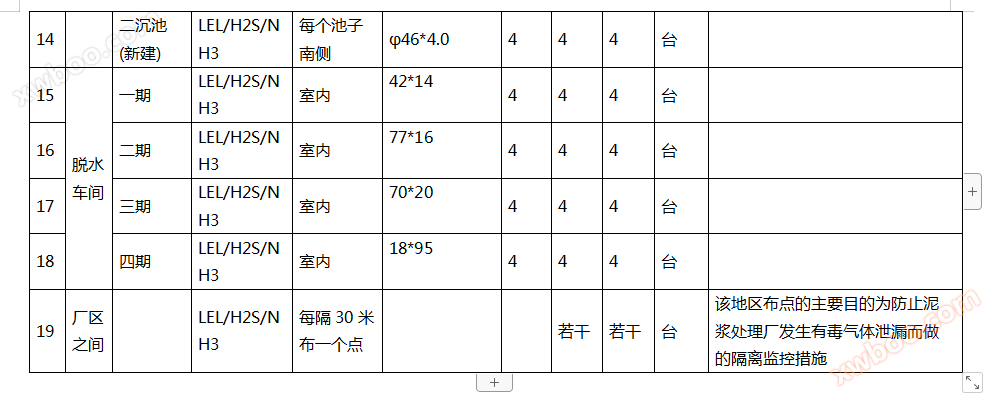

1.2 Detection distribution plan for each process section

1.2.1Process Flow Diagram

1. System Instructions

The gas detection system consists of the following components:

lCombustible (toxic) gas detector;——HA8100&HA8600Combustible and toxic gas detector

lCombustible (toxic) gas detection controller terminal cabinet&Control panel cabinet; ——HA6600&HA6100Disk mounted wall mounted option

lCombustible (toxic) gas detection system operation station;——Industrial computer(CPUP4,3.0G;memory1G;hard disk250G;belt22Inch LCD dual screen,32True color graphics processing display screen, network switch, and monitoring software (supporting)HMI)

lOn site sound and light alarm;

Basic functions:

lThe first level alarm is a gas leak warning, prompting operators to promptly go to the site for inspection and handling;

lThe second level alarm is an emergency alarm for gas leakage, prompting the operator to take emergency measures;

lWhen gas leakage requires linkage protection, the secondary alarm contact signal should be used as the linkage protection condition;

lThe on-site detector's built-in alarm accepts the first and second level alarm signals output by the detector, and the on-site area alarm acceptsGDSThe second level alarm signal output by the system.