1、 Basic parameters of cold and hot shock test chamber:

Product Structure Thermal Shock Testing Machine

Test temperature -40~150, -55~150, -65~150 ℃

Technical Specifications

Preheating temperature range for high temperature chamber: ambient temperature~200 ℃

warm-up time

≤ 35 minutes (run separately)

Low temperature chamber pre cooling temperature range: ambient temperature~-70 ℃

Cooling time ≤ 30 minutes (running separately)

studio

Temperature range -40 ℃, -55 ℃, -65~+150 ℃

Temperature accuracy ≤± 0.5 ℃

Temperature recovery time ≤ 5 minutes

Low temperature test ≥ 30 minutes

High temperature test ≥ 30 minutes

material

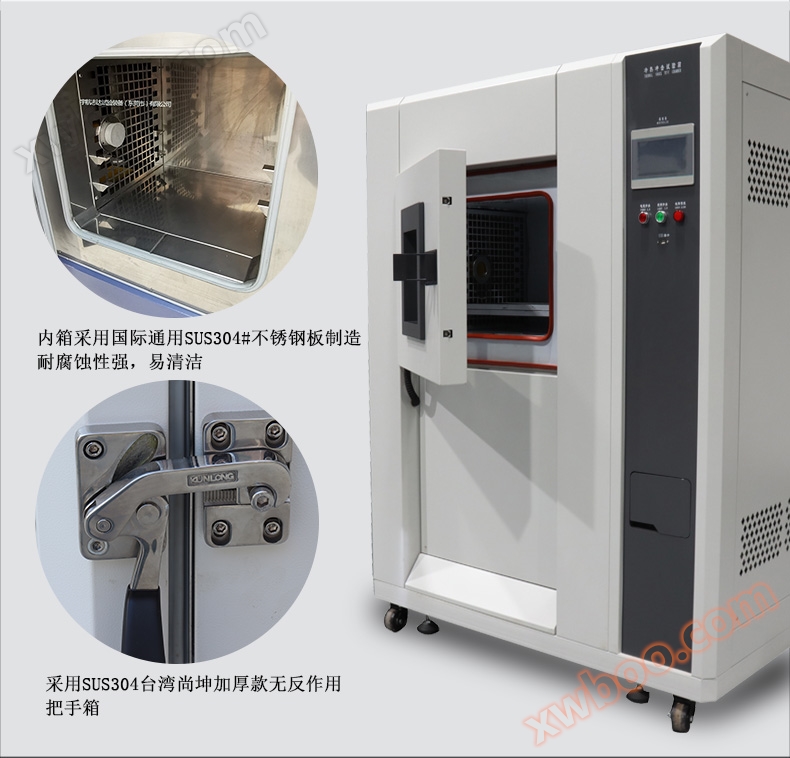

Outer box material: Cold rolled steel, electrostatic spraying

The material inside the three boxes is SUS304 stainless steel

Insulation material: ultra-fine glass insulation cotton

Component configuration controller: Korean ternary TEMI880S true color touch screen impact box dedicated program controller

Stainless steel finned heater

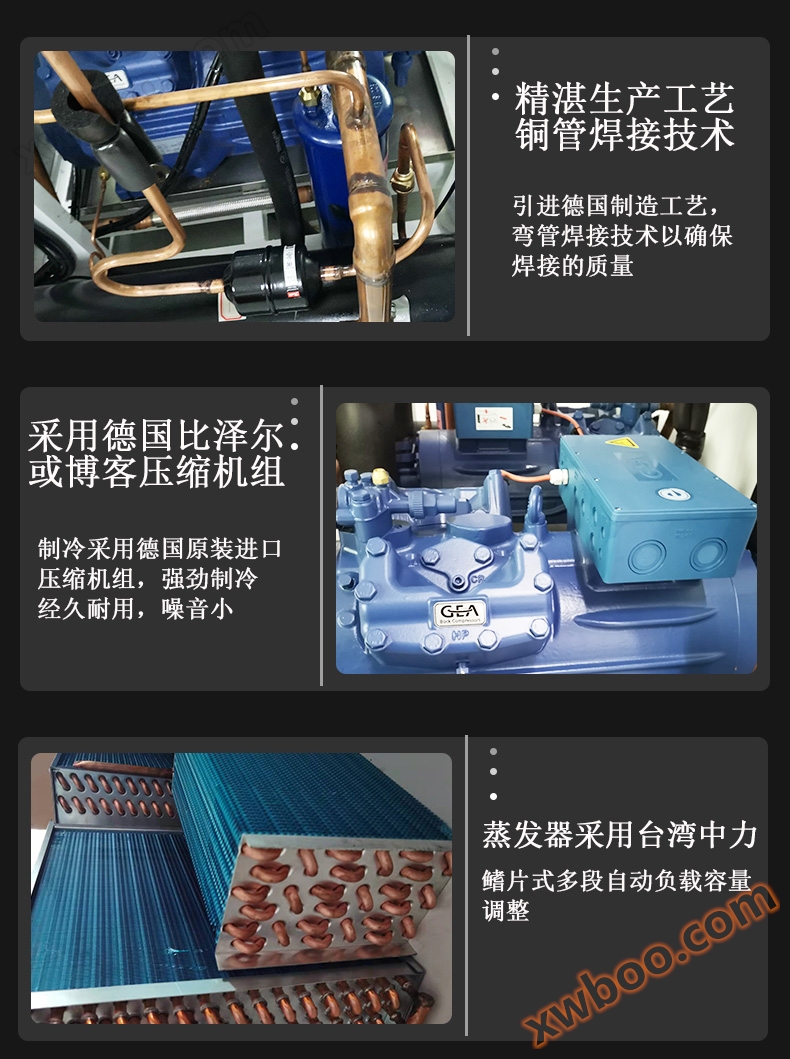

Refrigeration system compressor air cooling, water cooling

Cooling method

Single-stage refrigeration, two-stage refrigeration

refrigerant

Environmentally friendly R-404A, R-23

circulatory system

Stainless steel fan realizes forced air circulation, air door conversion, cylinder drive

Other configurations

One cable outlet with a diameter of 50mm for testing purposes; Bottom angle universal wheel

Hollow conductive electric defrosting function glass observation window and lighting lamp in the studio

2、 Specification and technical parameters of cold and hot impact testing machine:

Model (cm) YHZD-50 YHZD-80 YHZD-108 YHZD-150 YHZD-250

Studio size 36 × 35 × 40 50 × 40 × 40 60 × 40 × 45 60 × 50 × 50 70 × 60 × 60

Dimensions: 165 × 179 × 144 179 × 185 × 144 180 × 180 × 150 180 × 189 × 154 190 × 205 × 165

3、 Application of Thermal Shock Testing Machine:

The three box high and low temperature impact testing machine is used in industries such as electronics, automotive parts, metals, chemical materials, plastics, etc. to test the repeated tensile strength of various materials at high and low temperatures,

The physical damage or chemical changes caused by thermal expansion and contraction of experimental products can confirm the quality of the products, from IC to heavy mechanical components, and their recognition is necessary for everything.

4、 Structural characteristics of cold and hot shock testing machine:

1. The product has a beautiful appearance, reasonable structure, advanced technology, and carefully selected materials. It has simple and convenient operation performance and reliable equipment performance.

2. The cold and hot shock chamber is divided into three parts: high temperature chamber, low temperature chamber, and testing chamber. It adopts a unique heat insulation structure and thermal storage effect. During the test, the test object is completely stationary, and the cold and hot air paths are switched to introduce the cold and hot temperatures into the testing area to achieve the purpose of cold and hot shock testing.

3. Using measuring devices, what,? The controller adopts a large color LCD human-machine touch dialogue LCD human-machine interface controller, which is easy to operate,? Easy to learn, stable and reliable. Display complete system operation status, execution, and program setting curves in both Chinese and English. With 96 independent test specifications, the impact time is 999 hours and 59 minutes, and the cycle time can be set from 1 to 999 times. It can achieve automatic operation of the refrigeration machine, reduce the workload of operators, and automatically start and stop working at any time.

4. There is a test hole with a diameter of 50mm on the left side of the box, which can be used to test components for external power load wiring.

5. It can independently set the functions of high temperature, low temperature, and thermal shock under three different conditions. When executing the thermal shock conditions, it can choose between two slot or three slot and the functions of cold shock, hot shock, and thermal shock. It has the function of a high and low temperature testing machine.

6. Equipped with fully automatic, high system loop, any component action, fully P.L.C locking processing, all using P.I.D automatic calculation control, high temperature control accuracy.

7. Advanced scientific air circulation design ensures uniform indoor temperature and avoids any dead corners.

8. A complete protective device avoids any potential hazards and ensures the long-term reliability of the equipment.

9. Can the number of cycles and defrosting times be set automatically (manually)? In addition, the air outlet is detected and controlled by the return air outlet sensor, and the switching time of the air door mechanism is completed within 10 seconds. The recovery time of the cold and hot shock temperature is completed within 5 minutes. During operation, the status display and curve display automatically show the fault point and cause on the screen in case of abnormal conditions, and provide troubleshooting methods. It also has an emergency stop device when unstable input power is detected.

10. The refrigeration system adopts a cascade low-temperature circuit system design, and the refrigeration unit uses imported compressors from Europe and America, as well as green and environmentally friendly (HFC) refrigerants R507 and R23 with zero ozone coefficient.

Protection functions: power overload protection, leakage protection, control circuit overload, short circuit protection, compressor protection, grounding protection, over temperature protection, alarm sound prompt, etc.