The online printing, scanning, detection, and peeling system belongs to a functional integrated equipment machineOn the basis of the German printing host, intelligent scanning devices, label peeling devices, and industrial control systems have been installed. Through automatic scanning and 100% barcode verification technology, fines caused by barcode issues can be reduced. The online printing, scanning, and peeling system can analyze whether all barcodes printed by the barcode printer are correct. Given that a large number of companies use barcodes throughout their product supply chain, it is crucial to scan these barcodes correctly every time.

Product advantages

Avoid refunds caused by poor barcode quality

Automatically provide 100% scannable and correct barcodes to your user unit every time.

Prevent unqualified barcodes from entering your supply chain

The online printing, scanning, and peeling system can prevent non compliant (non scannable, duplicate) barcodes from entering your production or distribution system without interruption.

Reduce costs and improve efficiency

Reduce the labor time and cost of re barcode due to barcode quality issues.

Capture and display all barcode quality data

Grasp the core of the problem to reduce downtime, rework, and quality review time.

Realize important visualizations

Capture and display the raw data of each barcode, further ensuring the correct printing of key data such as consecutive barcodes.

Quickly isolate problem labels through an online printing system data manager

Save data to the database and export it, analyze and view information online, archive and export it in real-time to the database, thereby effectively establishing quality management archives.

printer management

Real time monitoring to see if your printer is functioning properly? If there is an inability to scan, you can immediately know that the printer is printing abnormally and replace the accessories immediately

Product Application

Multi functional application scenarios: The online printing, scanning, and peeling system has two application modes: online batch printing scanning and real-time online printing scanning peeling. Online printing, scanning, and peeling systems are more intelligent and convenient than traditional scanning after printing and manual scanning for online printing; (As shown in the figure below)

Mainly used in industries such as electronic assembly, home appliances, auto parts, wiring harnesses, printing, and food manufacturing

Technical Specifications

|

Online printing, scanning, and peeling all-in-one machine |

|

|

model |

A-S4xx(20/30/60) E/Plus |

|

Printing method |

Thermal/heat transfer printing |

|

print resolution |

203dpi/305dpi/609dpi |

|

The fastest printing speed |

4 inches/second~8 inches/second |

|

Maximum printing width |

105mm |

|

Maximum printing length |

1500mm (39 inches) |

|

Peel height |

Above 11mm |

|

label width |

Basic type: 15-120mm |

|

Ribbon length |

600M (1 "inner diameter, suitable for both inner and outer roll types) |

|

Carbon ribbon width |

25mm-110mm (1 inch -4.5 inches) |

|

Barcode system |

Universal one-dimensional code, two-dimensional code |

|

data interface |

RS232 serial port, USB port, Ethernet port, IEEE 1284 bidirectional parallel port, EXT external communication port |

|

Power supply and total power |

100-240 V single-phase AC, 50-60 Hz, 300W |

|

Accessories (optional) |

IO signal board, peeling and rewinding, label peeling sensor, label rewinder, small label sensor |

|

Intelligent scanning device |

AITGM, NewLand, OMRON, Datalogic, Honeywell (choose corresponding models based on barcode accuracy and application, and overall equipment prices also vary) |

|

printing system |

AITGM-OPS printing and scanning complete system (barcode definition, rule definition, anti duplication code judgment, backend database, data export), connected to NL6 genuine printing software |

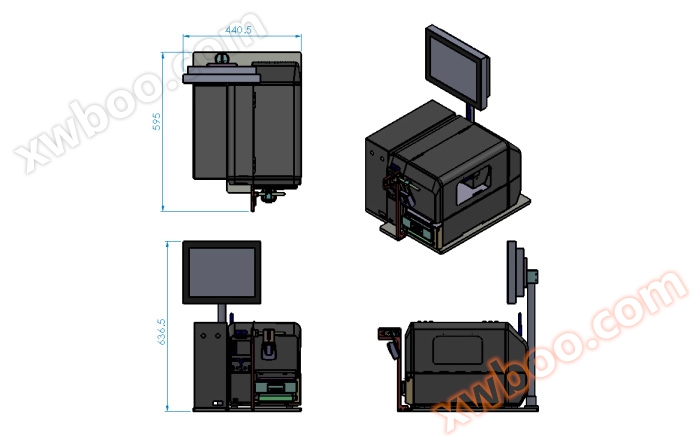

Overall dimension diagram of online printing and scanning equipment