|

The POV-500 clean oven has a wide range of applications: it is suitable for baking items with chemical gases and food processing industries, removing substrate stress, curing ink, drying paint films, etc. Widely used in precision baking, drying, tempering, preheating, shaping, and processing of electronics, motors, communications, electroplating, plastics, hardware chemicals, food, printing, pharmaceuticals, PC boards, powders, impregnation, spraying, glass, ceramics, wood building materials, and more.

|

|

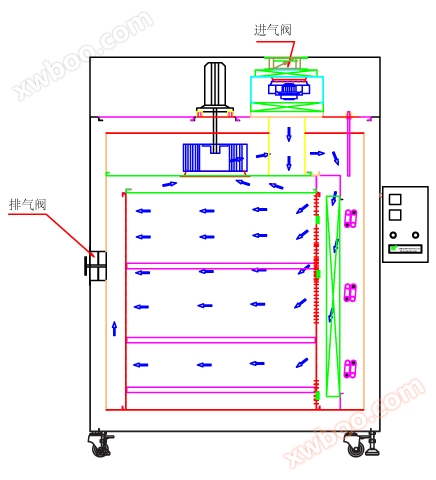

The air circulation system adopts a dual motor horizontal circulation air supply method, with uniform and efficient air circulation. The air source is driven by a circulating air supply motor (using a contactless switch) to drive the wind wheel (Φ 230) through an electric heater, and then the hot air is sent out through an air duct to the interior of the oven. The used air is then sucked into the air duct to become the air source for further circulation and heating. Maintain indoor temperature uniformity. When the temperature value fluctuates due to the action of opening and closing the door, the air supply circulation system can quickly restore the operating temperature value. |

|

|

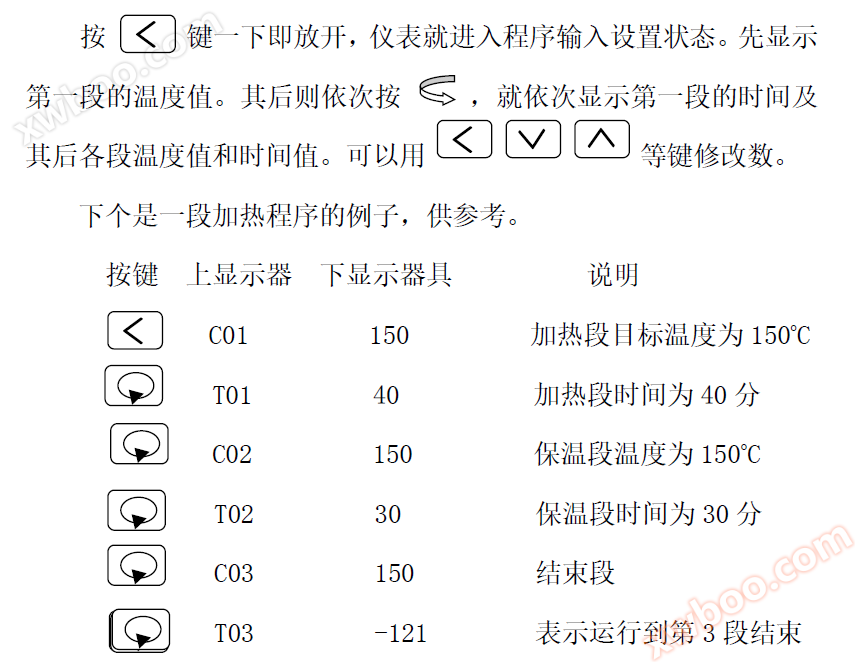

1. After connecting the power supply, the heating switch can be turned on. For the clean oven, turn the temperature setting dial to the desired working temperature value, set the temperature "Set Measure" switch to "Set", adjust the temperature setting knob to the desired working temperature, and then turn the "Set Measure" switch to "Measure". At this point, the temperature inside the oven starts to rise and the green light is on. |

The work area is made of all stainless steel structure, which is bright and clean

Stainless steel chain switch ensures the sealing of the cabin

Programmable controller control, stable and reliable

The airflow pattern is horizontal or vertical unidirectional flow

Good insulation, with a high temperature of up to 250 ℃ inside the oven and a shell temperature not exceeding 40 ℃

A groove shaped track is installed at the bottom of the oven to facilitate the material cart to be pushed in for drying

Hot air circulation, uniform temperature, top exhaust gas removal, improved curing time, enhanced workpiece quality, high work efficiency

Equipped with explosion-proof devices and a pressure relief safety door on the back, it ensures the safety of drying operations under special heating conditions

| texture of material:External steel plate baked paint, internal cavity made of 304 stainless steel structure |

|

Cleanliness:Class A |

|

|

|

|

| Noise:≤55dB(A)@0.3m/s |

|

Weight:250kg |

|

|

|

|

| Temperature range:50~250℃ |

|

Temperature fluctuations:±1℃ |

|

|

|

|

| Workplace size:500*500*1000mm |

|

power waste:≤5kw |