VIP member

630 ton gantry hydraulic press

The 630 ton gantry hydraulic press, also known as the frame hydraulic press, adopts computer optimized structural design. The structure is made of all

Product details

The 630 ton gantry hydraulic press, also known as the frame hydraulic press, adopts a computer optimized structural design. The structure is made of all steel plate CO2 welding to ensure the deformation of the machine body. The equipment has high strength and good stability, simple operation, low energy consumption, low noise, easy operation, easy maintenance, economic durability, long service life, low hydraulic impact, independent electrical control system, reliable operation, intuitive action, and easy maintenance. Adopting button centralized control, it can achieve three operation modes of adjustment, manual, and semi-automatic, as well as two molding processes of fixed pressure and fixed distance. It has a pressure holding delay function and adjustable delay time. The work pressure and travel can be adjusted within the specified range.

Technical parameters of 630 ton gantry hydraulic press:

Nominal force 630KN

The liquid has a high pressure of 25Mpa

Slide stroke 800mm

Large opening size 1200mm

Workbench area (left and right x front and back) 1000 x 1000mm

Slide size 800 × 800mm

Workbench height (front desk) 600mm

The total weight of the machine is about 12mm

The external dimensions of the host are 2000 * 1200 * 5000mm

Motor power 22KW

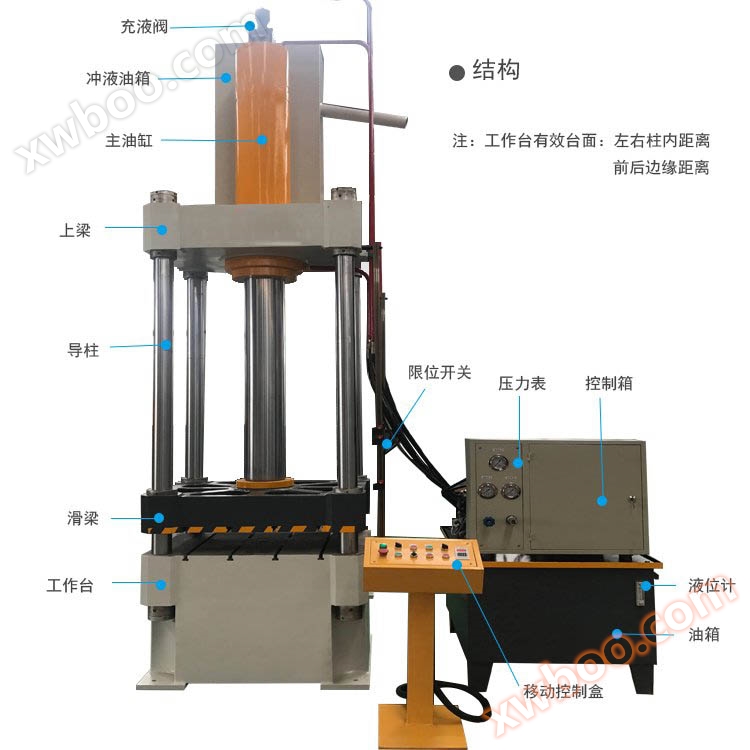

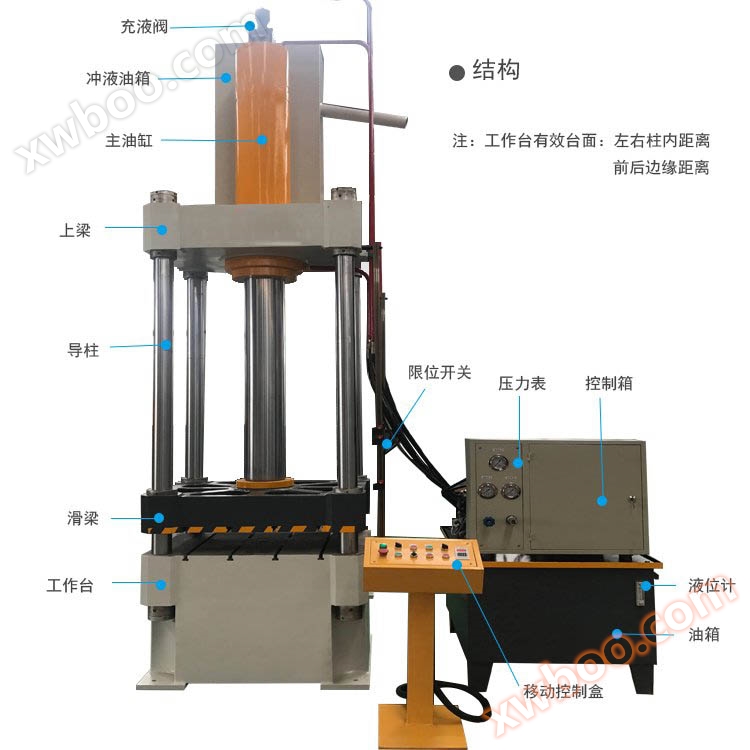

Overview of the structure of the 630 ton gantry hydraulic press:

1. The body of the 630 ton gantry hydraulic press adopts a gantry frame structure, consisting of upper crossbeam, slider, worktable, main cylinder, hydraulic power system, and electrical system. The upper crossbeam, slider, and worktable are welded with high-quality steel plates, and subjected to high-frequency vibration welding stress after welding. The column of the 630 ton gantry hydraulic press is made of high-quality 45 # steel, with surface medium frequency quenching and chrome plating treatment.

2. The compression cylinder tonnage of the 630 ton frame hydraulic press is achieved by a single piston cylinder. The cylinder body is made of high-quality forged steel, and the surface of the piston rod is treated with medium frequency quenching, resulting in high hardness and long service life. The main sealing components of the oil cylinder use excellent sealing rings to ensure reliable sealing.

3. The worktable and slider of the 630 ton gantry hydraulic press have T-shaped grooves, which are convenient for users to install molds.

630 ton gantry hydraulic press product features:

1. Frame structure, good rigidity and high precision.

2. The hydraulic control adopts a plug-in valve integrated system, which has low impact, reliable action, long service life, and few leakage points.

3. The new type of oil cylinder sealing element has strong reliability and long service life.

4. The stretching and edge pressing sliders can be connected together to achieve single action process actions.

5. Automatic lubrication device for guide rails.

6. Mechatronics device. For example, the support circuit of the lower chamber of the oil cylinder, the interlocking circuit of the upper and lower chambers of the oil cylinder, etc., have superior performance.

7. The electrical system can be controlled by PLC.

8. It can achieve two molding processes of fixed pressure and fixed distance, with pressure holding delay function and adjustable delay time.

9. The work pressure and stroke can be adjusted within the specified range according to the process requirements, and the operation is simple.

Precautions for operating a 630 ton frame hydraulic press:

1. The 630 ton gantry hydraulic press should be properly grounded, preferably separately grounded.

2. The 630 ton frame hydraulic press is not allowed to calibrate the mold during operation.

3. The hydraulic oil is N46 anti-wear hydraulic oil or N46 low pour point hydraulic oil, which is filtered through an 80-100 molybdenum wire mesh before use.

4. After working for 200 hours, the cleanliness of the oil in the 630 ton gantry hydraulic press should be checked, and there should be no odor. Drop a drop of oil on the white filter paper, and there should be no black stains within the center point of the oil stain. Otherwise, change the oil.

5. The 630 ton gantry hydraulic press shall not be overloaded for use.

6. If there is an unexpected leak in the system, sufficient hydraulic oil should be replenished after the malfunction.

7. Regularly check the pump station and oil tank for cleanliness, and strictly prohibit water, dust, and foreign objects from entering the oil tank.

8. If the conversion function is needed, the air inside the system should be completely purged before it can work.

9. If there are any abnormalities during testing and operation, the machine should be stopped immediately for inspection.

10. Maintaining pressure for 10 minutes allows for a pressure reduction of 2.5Mpa.

Optional accessories:

1. Punching buffer device

2. Mobile Workbench

3. Light curtain protection device

4. Cooling device

5. There are floating guide rails and rolling brackets for mold replacement

6. Touch mode industrial display screen

7. Material feeding device (hydraulic press and mechanical)

8. Work light

9. PLC programmable control system

Scope of application of 630 ton frame hydraulic press:

The 630 ton gantry hydraulic press is an economical hydraulic press designed for your processing needs. It is suitable for pressing metal and non-metal materials such as clocks, hardware products, bicycles, motorcycles, tableware, kitchenware, automobiles, appliances, rubber, grinding wheels, buttons, gold and silver jewelry, ceramics, powder metallurgy, etc; Stamping and forming work of plastic materials. The 630 ton gantry hydraulic press is suitable for various large, medium, and small enterprises, factories, industrial and mining areas, and automobile repair shops. It is used for heavy-duty machinery, flange plates, belt pulleys, shaft bushings, bearing disassembly and assembly operations, straightening and correction, bending, and punching with molds. It can replace the old-fashioned screw rotary hand press for pressing operations with material dropping, stretching, and folding, truly achieving multi-purpose use of one machine.

Online inquiry