Product Usage:

The 1200mm HDPE pipe production line is a large-scale pipe production equipment. Large sized HDPE pipes are widely used in public works such as water supply and drainage, natural gas transportation, etc.

Advantages:

High output and stable operational performance.

PLC automatic control system and HMI touch screen control panel.

Mold temperature automatic control system.

● Meter weight system.

Adopting the most advanced spiral mold structure design.

The traction machine is driven by servo motors, with a wide speed range and good stability. Equipped with a winch, it is easier to pull the pipe in the initial stage.

● Chip free cutting machine, suitable for PE pipes with different diameter ranges.

Reliable performance and high production efficiency.

Equipment composition:

Single screw extruder+co extrusion machine+pipe mold+vacuum sizing box+cooling spray box+six jaw crawler tractor+chip free cutting machine+Flipping rack.

Technical Specifications:

|

host |

|||||||||

|

extruder |

model |

aspect ratio |

host power |

speed |

Output (kg/h) |

||||

|

Single screw extruder |

SJ-120/38 |

38:1 |

355kw |

94rpm |

1100-1200 |

||||

|

Auxiliary machine (630-1200mm) |

|||||||||

|

Vacuum sizing box 1 unit |

Spray cooling box 2 units |

cutter |

cutter |

Flipping rack 2 units |

|||||

|

Length: 12000mm |

Length: 6000mm |

12 claw track type |

Shaftless cutting |

Length: 4000mm |

|||||

|

Vacuum pump: 5.5kw * 6 units |

Water pump: 7.5kw * 2 units |

Servo motor 0.85kw * 12 units |

Cutting power: 7.5kw |

||||||

|

Water pump: 7.5kw * 6 units |

0-0.5 meters per minute |

||||||||

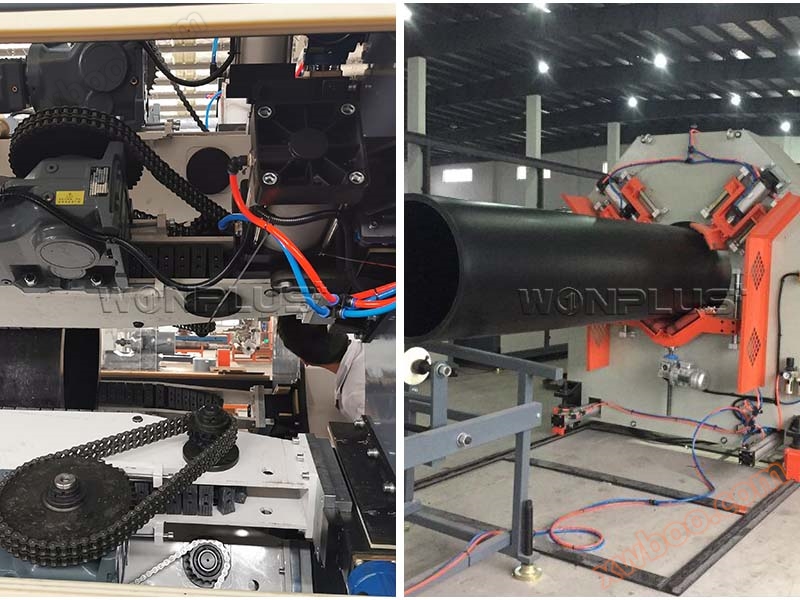

Picture introduction of extruder production line: