VIP member

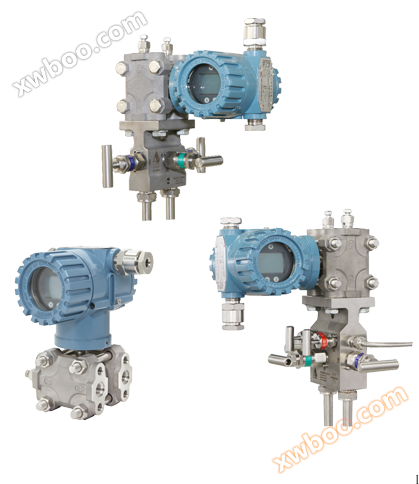

361R series monocrystalline silicon micro differential pressure transmitter

The measurement of flow rate, liquid level, and pressure adopts HART fieldbus technology, which can provide more on-site information to improve the pe

Product details

performance index

The overall performance is based on the comprehensive error of reference accuracy, environmental temperature influence, and range static pressure influence.

Accuracy index

± 0.2% FS range (conventional)

stability

≤ 0.3% FS/5 years

Specific performance indicators

Zero based range, reference conditions, silicone oil filling, 316 stainless steel isolation diaphragm, 4-20mA analog output, digital fine adjustment value equal to the range set point value. )

accuracy

(Reference accuracy includes hysteresis, terminal based linearity, setting capability, and repeatability)

± 0.2% range

If the range is less than 0.4KPa

±[0.15+0.09× ]%

]%

]%

]%Static pressure effect

0.3% FS/4MPa (only 6KPa range)

Zero point impact

The zero position can be adjusted on-site according to the installation location, or the pressure zero position can be relocated.

Damping time constant

The total damping time constant is equal to the sum of the damping time constants of the amplifier component and the diaphragm box. The damping time constant of the amplifier component can be adjusted within the range of 0-100 seconds.

Membrane box (silicone oil)

Time constant (seconds) (can be set according to the actual situation on site, recommended: 1KPa 2S/6KPa 1S)

Installation location impact

The installation position change parallel to the membrane surface will not cause zero drift. If the installation position changes more than 90 degrees from the membrane surface, zero drift within the range of 0.4KPa can be corrected by zero adjustment without affecting the range.

Power supply impact

Less than ± 0.005% range/volt

Functional indicators

Range and Sensor Limit Values

Table 1.361R transmitter range and sensor limit values

Zero point and range adjustment requirements

·The zero point and range can be adjusted arbitrarily within the range limits indicated in Table 1.

·The range must be greater than or equal to the minimum range indicated in Table 1

Application scenarios

Measurement occasions for liquids, gases, and vapors

output

Two line 4-20mA, users can choose linear output or square root output. The digital process variable is superimposed on a 4-20mA signal and is suitable for any host that complies with the HART protocol.

power supply

External power supply is required. The standard transmitter (4-20mA) operates at 14.5-45V DC when unloaded.

Circuit load limit

The maximum circuit resistance is determined by the external power supply voltage, and the relationship is as follows:

Note: The power supply voltage range for transmitters with backlit display screens is 14.5-45V

The power supply voltage range of intrinsic safety series transmitters is 14.5-28V

The working voltage during HART communication should be greater than 17.5V

Static pressure limit and maximum overpressure

Range E: Unidirectional overvoltage 200KPa

Range L: Unidirectional overvoltage of 4MPa

Fault mode

output code

When a fault is detected in the sensor or microprocessor during self diagnosis, the transmitter drives the output of a high or low alarm signal to alert the user. The alarm output value depends on the factory configuration of the transmitter:

Linear output: 3.8<I<20.8

C4: I=20.8mA fault high

CN: I=3.8mA fault low

Temperature Limit

environment

-20 ℃ to+70 ℃ (normal)

-40 ℃ to+85 ℃ (maximum)

-40 ℃ to+85 ℃ (maximum)

keep in storage

-46 to 110 ℃

With header: -40 to 85 ℃

process

At atmospheric pressure greater than or equal to, see the table below

Table 2.361R transmitter process temperature limit

temperature drift

≤0.15%FS/10℃

Humidity limit

0-100% relative humidity

Start Time

The transmitter reaches its performance indicators within 2 seconds of being powered on

Mechanical performance indicators

electrical interface

ANSI (American Standard) NPT1/2 (F) internal thread

ISO M20 × 1.5 internal thread

process interface

No process joint (NPT1/4 internal thread on chamber flange)

With "waist" shaped connector: NPT1/2 cone tube internal thread

With "T-shaped" joint: M20 × 1.5 external thread and rear welded pressure pipe (stainless steel)

Equipped with a "waist" shaped joint and NPT1/2 pressure crossing head and rear welded pressure pipe (stainless steel)

Process liquid receiving components

Process isolation membrane: 316L stainless steel, Hastelloy C

Drain/exhaust valve

316 stainless steel

Process flanges and joints

Carbon steel plated with cadmium, 316 stainless steel

Non liquid parts

Electronic housing

Die cast aluminum IP65

coating

Powder coating

Cover O-ring

Nitrile rubber

• Adopting MEMS monocrystalline silicon high-precision pressure sensor

Fast response speed and high stability

Measurement accuracy 0.2% FS, maximum 0.1% FS

The maximum range ratio can reach 20:1

Adopting dual overload protection technology

Strong overload capacity, unidirectional pressure can reach 4MPa

• Provide standard HART bus communication mode

• Comprehensive self diagnosis and remote communication functions

LCD display with backlight and high brightness

• 360 degree rotatable on-site display screen

• Convenient on-site reset function

Convenient on-site zero and full point setting and calibration functions

Convenient on-site current circuit verification function

Online inquiry